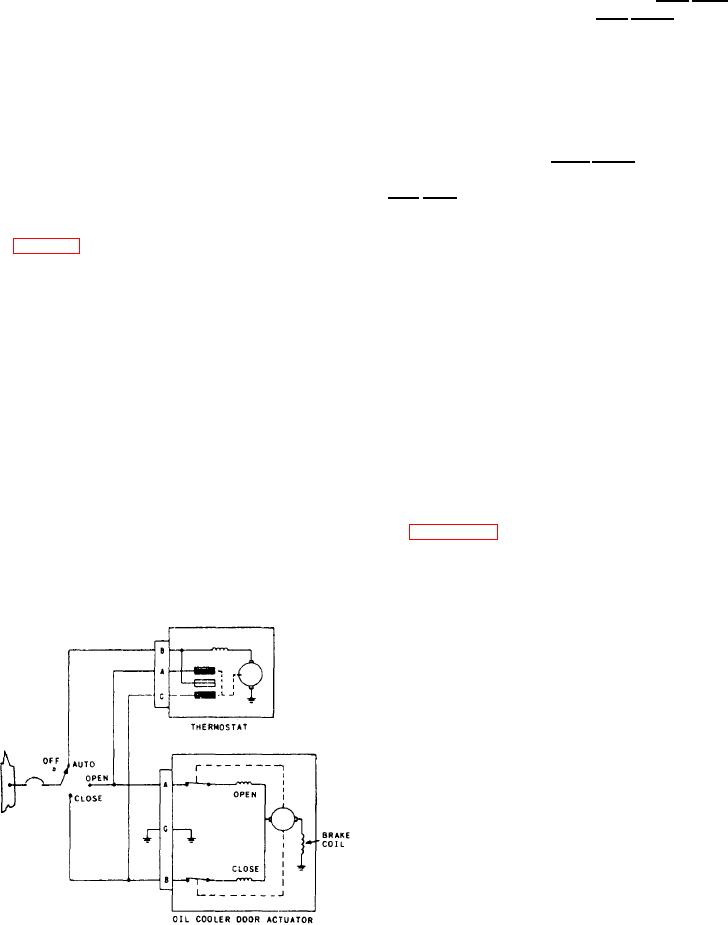

One of the floating contacts is in the door open

Q3. When does the fuel transfer center of

circuit and the other is in the door closed circuit.

gravity control system energize?

The two arms rest on a cam, which a small

motor constantly rotates. Thus, the floating

contacts are constantly vibrating toward the

central contact.

OIL TEMPERATURE CONTROL

When oil temperature rises above normal, the

SYSTEM

thermostatic element causes the central contact

Learning Objective: Recognize operating

to move toward the d o o r o p e n contact. As

principles and characteristics of aircraft

the contact vibrates, it intermittently closes the

door open circuit. As the actuator intermittently

engine oil temperature control systems.

energizes, the door slowly opens. When the oil

temperature returns to normal, the central contact

The cooling capacity of the oil cooler system

(fig. 5-15) in an aircraft depends on the airflow

moves back to a neutral position.

that passes through the cooler. Airflow is

When oil temperature falls below normal, the

controlled by an oil cooler door actuator, which

central contact moves in the opposite direction,

varies the oil cooler air exit duct.

closing the door. To prevent excessive hunting

The door actuator is a split-field, reversible

of the system, a tolerance is maintained by

an adjustment of the cam on the floating

dc motor. It includes a magnetic brake for

contact.

stopping it quickly when it reaches the limits of

travel. The control switch has four positions--

When the oil temperature rises high above the

OPEN, CLOSE, AUTOMATIC, and OFF. In the

normal value, the central contact lifts the floating

OPEN or CLOSE position, electrical power goes

contact clear of the cam, completing a continuous

to the actuator, which opens or closes the oil

circuit. The door then moves to the full open

cooler door. When the switch is in AUTO-

MATIC, a thermostat controls the actuator.

position where a limit switch in the actuator

breaks the circuit.

The thermostatic control unit is in the oil

return line. The unit contains two floating contact

Figure 5-16 shows another type of engine oil

arms and a central contact arm that actuates by

temperature regulator. This regulator has a

a bimetallic coil immersed in the oil return line.

mercury-filled thermostat, and relays auto-

matically control the position of the engine oil

cooler doors. When the engine temperature is low

requiring more heat, the two relays energize,

allowing the oil cooler door to close. As the

temperature increases, the thermostat completes

a path to ground, bypassing the relay coils and

de-energizing them. Power then goes through the

contact of one of the relays, opening the actuator

coil and causing the oil cooler door to open and

reduce engine temperature.

VARIABLE EXHAUST NOZZLE

CONTROL SYSTEM

Learning Objective: Recognize operating

conditions and features of aircraft engine

variable exhaust nozzle control systems.

As you read this section, refer to the simplified

schematic diagram of a typical variable exhaust

Figure 5-15.-Oil temperature control circuit.