propeller blade angle errors. (Figure 5-20 shows one

error circuits receive no signal. With the sawtooth in

channel of the synchrophasing circuit.)

the positive region, tube V205 conducts. The

The following paragraphs describe phase and

corresponding voltage changes go to the grid of phase

speed error sensing.

difference tube V206A.

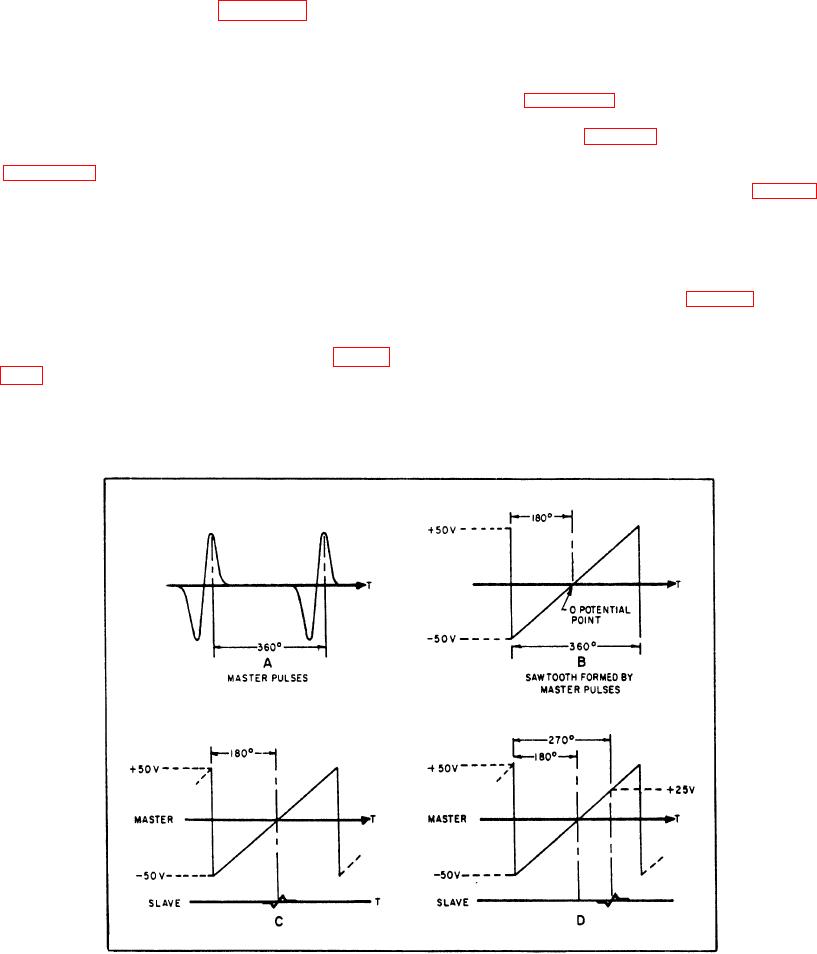

You can see the nature of the sampling action by

referring to figure 5-21. The time interval between

SAWTOOTH FORMER.--The pulse from the

master pulses is the time interval for 360 degrees of

master pulse generator is transformer-coupled to the

propeller rotation (fig. 5-21, view A). The time interval

sawtooth former. The slave pulse generators are

of the sawtooth, which the master pulse generates, is

transformer-coupled to the channel sampler circuits.

360 degrees. The half-time interval, or 180-degree

Figure 5-21, views A and B, shows the master pulse

position, is the sawtooth zero potential point (fig. 5-21,

and the resultant sawtooth formed in the sawtooth

view C). When the slave pulse occurs at the zero point,

former.

the propellers are on phase with a 180-degree phase

difference between them. All references to slave

SAMPLING CIRCUITS.--Pulses from the three

pulses are with respect to the 360-degree interval. The

slave engines couple to the grids of the sampling

point of occurrence of the slave pulse determines the

circuit tubes, while the sawtooth voltage goes to the

signal size in the sampler circuit (fig. 5-21, view D).

plate of one tube and the cathode of the other tube in

This signal represents the phase difference between

all sampling circuits. The positive-going portion of the

propellers.

slave pulse places the tubes in a conductive state.

(Sampling is the same in all channels.) Refer to figure

NOTE: Since the propellers are four-bladed, the

5-20. If the sawtooth is at zero potential when the

relative blade position between the master and slave

slave pulse occurs, neither tube conducts, so the phase

propellers is exactly the same when the slave

difference

and

speed

Figure 5-21.--Master and slave pulse comparisons.

5-37