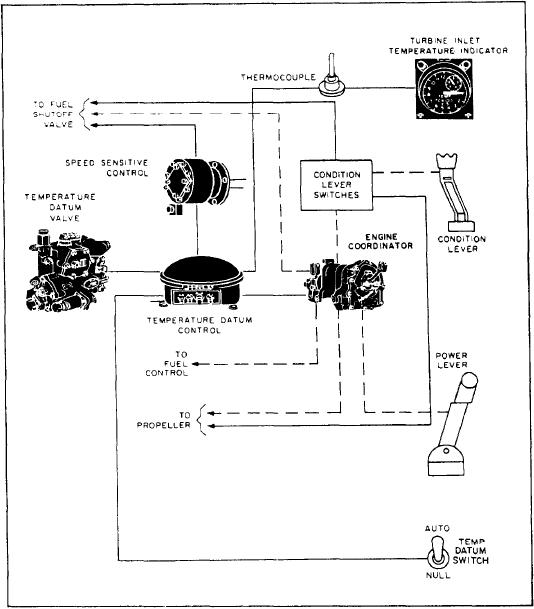

Figure 5-7.-Engine temperature control (turboprop) system block diagram.

changes in fuel density, manufacturing tolerances

power lever is below 66-degree coordinator

in fuel controls, and variations in engine fuel

(temperature limiting range), the normal limiting

requirements between engines. With the power

temperature automatically becomes 978C

lever above 66-degree coordinator (temperature

(1,792F). However, when engine speed is below

94 percent RPM, regardless of power lever

controlling range) and the TEMP DATUM switch

in AUTO, the temperature datum control

position, the limiting temperature is 830C

compares the actual turbine inlet temperature

(1,524F). This prevents high turbine inlet

signal and desired temperature reference signal.

temperature during starting and acceleration when

If there is a difference greater than 1.9C (4.5F),

the compressor bleed valves are open.

Dual-unit thermocouples are mounted radially

the control electrically signals the temperature

in the turbine inlet case of each engine. The

datum valve to reduce or increase fuel flow to the

engine. This action brings the turbine inlet

junction portion of the thermocouples protrudes

temperature to the desired value. A damping

through the case to sense the gas temperature

voltage goes back to the control from a generator

before the gas enters the turbine section. Four

within the temperature valve motor, preventing

leads, two of Chromel and two of Alumel,

overcorrection and stabilizing the system. When

connect to each thermocouple to form two

engine speed is above 94 percent RPM and the

independent parallel circuits. One circuit connects

5-11