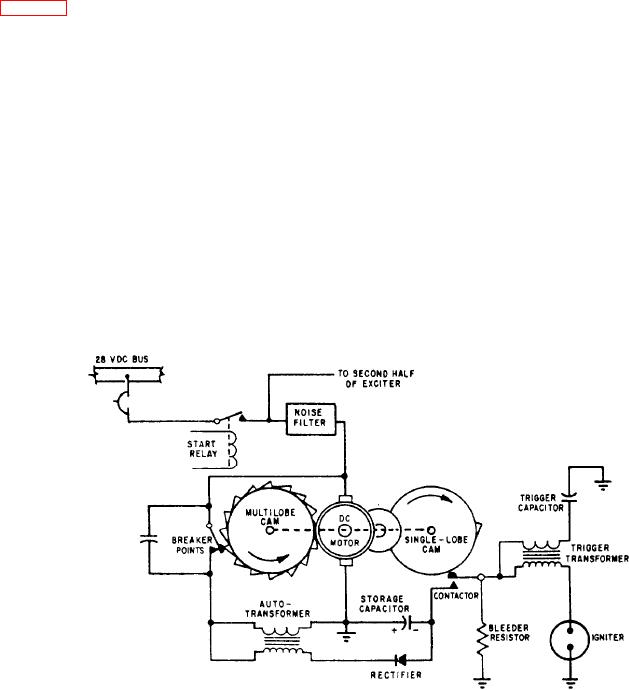

The ignition system gets its input power from

triggering transformer increases the output voltage

the low-voltage dc power supply of the aircraft

of the ignition unit and ensures reliability of the

electrical system. Its function is to produce high

system.

The igniter spark rate varies in proportion to

energy, capacitance-type sparks at the spark

igniters in the engine.

the voltage of the dc power supply, which affects

Input power from the low-voltage supply

the speed of the motor. However, as the same

connects through a noise filter to a dc motor. The

shaft operates both cams, the storage capacitor

motor drives a multilobe cam that operates two

always accumulates its energy from the same

breakers, and a single-lobe cam that operates two

number of pulses before discharge.

contractors. One breaker and one contactor

associate with each side of the system. The two

sides are identical. The following description

applies to either side.

CAUTION

When the multilobe cam closes the breaker

(fig. 5-5), input current flows through the

Due to the high voltage and amperage of

autotransformer's primary winding, establishing

this system, you should use extreme

a magnetic field. Then the breaker opens, the flow

caution around the equipment.

of current stops, and the field collapse induces

about 1,000 volts in the secondary. This voltage

causes a pulse of current to flow into the storage

ELECTRONIC IGNITION SYSTEM

capacitor through a rectifier that limits the flow

The development of more powerful jet engines

to a single direction. You can see that each time

the breaker opens, the capacitor receives a charge

demands a reliable, maintenance-free ignition

of electricity, and the action of the rectifier

system. This chapter doesn't cover all ignition

prevents any loss of this charge. After 34 such

systems; rather, the system described represents

pulses accumulate a charge on the capacitor, the

most modern systems. An electronic ignition

contactor closes by mechanical action of the

system has an advantage over the capacitor-

single-lobe cam. Then, the capacitor discharges

discharge system; it has no moving parts and

its stored energy through a triggering transformer,

breaker points or contractors that can become

and the energy dissipates at the igniter. The

pitted or burned.

Figure 5-5.-Functional schematic of capacitor-discharge system.