shelvings or carousels and MHE such as high rise stock

pickers.

MANPOWER

Planning the layout should include a projection of

work schedule and manpower requirements of the

supply operation. The layout must accommodate the

use of MHE and time of manual operations. For

example, if two MHEs are needed to accomplish one

day’s production in a storage area, the transportation

aisles should be wide enough to accommodate them.

On the other hand, operating in multiple shifts will

require reduced equipment requirements and smaller

aisle dimensions. Only one MHE, for the use of first

and second shift, will be required to accomplish one

day’s production.

MATERIAL FLOW

Plan the storage layout to ensure an orderly flow of

material. The most critical flow area is located where

various operations meet and interact. These areas must

have balanced throughput and accumulation space to

operate efficiently. The flow pattern that you can use is

either the cyclic or the straight line flow. The type of

flow pattern selected depends upon several factors.

These factors include the function of the facility,

relationship between receiving and shipping

operations, and the relative size, weight, and quantity

of material receipts and shipments.

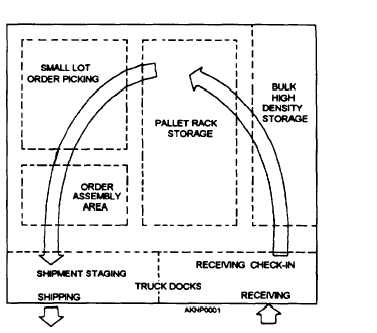

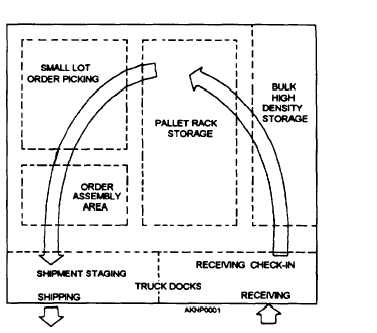

The cyclic flow pattern is useful for low or moder-

ate storage activities. It permits an efficient use of

internal material transport system in moving materials.

It allows the transport of material from the receiving

area to storage, to order picking, and to shipping docks.

Figure 2-1 illustrates a typical cyclic-flow pattern.

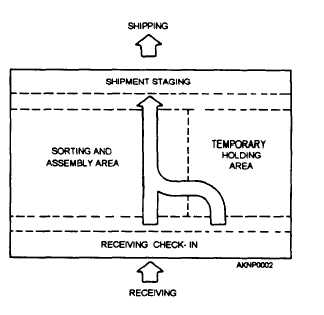

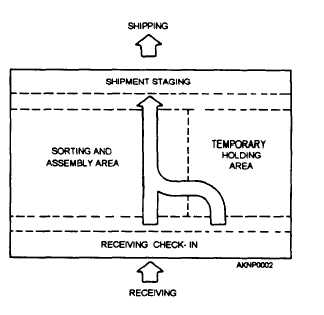

The straight line flow is used in high activity

operations where the material does not go to

intermediate storage. The typical application of this

pattern is in a high activity freight distribution area. In

this case, the activity receives loads of commodities,

sorts them by destination, and reloads them to outbound

trucks. This flow pattern emphasizes rapid and direct

transfer of material from receiving to shipping. Figure

2-2 illustrates a sample straight-line flow pattern.

SPACE UTILIZATION

In planning the storage facility, the space-

utilization layout includes the site space of the building,

floor area, and the building “clear height.” Planning the

Figure 2-1.-Typical cyclic-flow pattern.

site of the building is a job for engineers and architects.

You may be involved with planning the warehouse floor

area and “clear height” for maximum storage

utilization. The following text describes some factors

that you should know before you do the plan.

Utilization of Floor Area

The storage pattern for facilities used for pallet rack

operations is designed according to the MHE that will

be used to move the material. The dimensions of the

aisles depend upon the size of the forklift trucks.

Material handling and storage methods used to actually

Figure 2-2.—Typical straight-tine flow pattern.

2-4