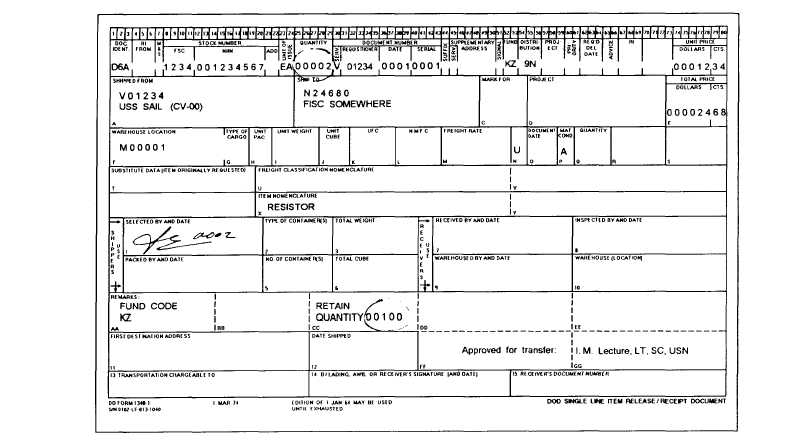

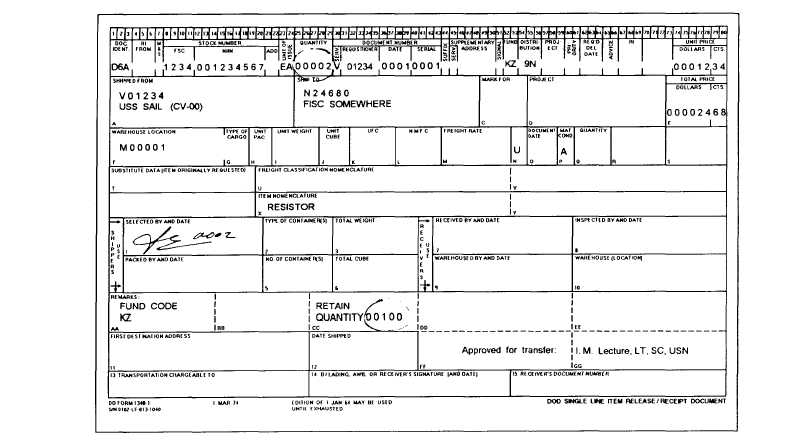

Figure 7-13.-Offload and retain quantity documentation on DD Form 1348-1.

When the OFFLOAD and RETAIN QUANTITY

both agree with the document quantity, process as

follows:

. Pull and stage the offload quantity.

. Circle both quantities on DD Form 1348-1 and

initial/date the document. (See figure 7-13.)

. Attach copies 2, 3, and 4 with the material.

. Return copy 1 (original) and remaining copies of

DD Form 1348-1 to stock control to update files.

When the total quantity in stock is less than the

retain quantity on DD Form 1348-1, do not offload the

material. Process the document as follows:

. Line out the offload quantity; enter 0 (zero)

above the quantity, and circle the 0 (zero).

l Line out the retain quantity; enter and circle the

actual quantity on hand.

l Initial and date the DD Form 1348-1.

. Return the DD Form 1348 to stock control for

further processing. (See figure 7-14.)

When the retain quantity equals the document but

the offload quantity is different, it requires an inventory

adjustment. Process the document as follows:

l Circle the retain quantity.

. Line out the offload quantity; enter and circle the

quantity actually located and staged for offload.

. Line out the total price in block E and enter the

new total price.

. Initial and date the DD Form 1348-1.

l Attach copies 2, 3, and 4 to the material.

. Return copy 1 (original) and remaining copies of

DD Form 1348-1 to stock control for further processing.

(See figure 7-15.)

PACKAGING, MARKING, AND

CONTAINERIZATION FOR TURN-IN

Materials for offload or shipment must have some

kind of protection to prevent damage during handling.

The NAVSUP P-484 provides basic procedures on

7-22