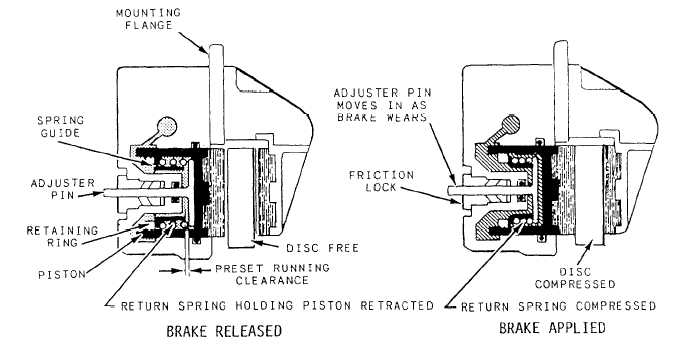

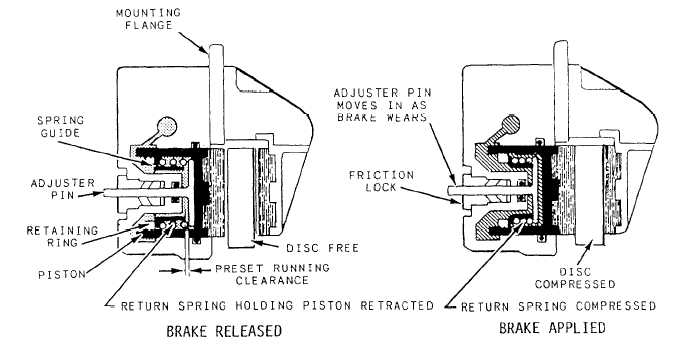

Figure 12–47.—Brake self-adjustment feature—single disc brake.

Proof testing is accomplished by applying 4,500 psi

individualy to each port with the opposing port plugged.

Maintain the pressure for 2 minutes, and there should be

no leakage. Conduct this check a minimum of three

times, and during the last proof test, rotate the swivel

through a complete swiveling circle. Conduct the static

leak test in the same manner as the proof test using 5 to

10 psi. Next, apply 3,000 psi to both the normal and

emergency ports with the opposing ports plugged.

Gradually, apply and check the torque required to rotate

the swivel. Maximum torque required should not exceed

30 inch-pounds.

In the final step of testing, apply low pressure to

each port with the opposing port unplugged, and check

to ensure that fluid flows freely through the swivel. If

the swivel is RFI and is to be returned to supply for stock,

flush it with preservative hydraulic fluid and plug all

ports. If the part fails the testing, tag it to show the part

of the test failed. Flush with preservative hydraulic fluid

and plug the ports. Forward the part to supply to be

forwarded to the next higher level of maintenance.

BRAKE ASSEMBLY MAINTENANCE

Learning Objective: Identify the maintenance

procedures for the single disc, the dual disc,

and the bimetallic disc brake assemblies.

The description and operation of the single disc,

dual disc, multiple disc, and segmented rotor brake

assemblies were covered earlier in this chapter.

Additional maintenance information on the single and

dual disc brake assemblies and a description and

operation of the trimetallic disc brake assemblies are

covered in this section.

SINGLE AND DUAL DISC BRAKES

Automatically adjusted single and dual disc brakes

are designed to provide a satisfactory running clearance

between the brake disc and the brake linings. The

self-adjusting feature of the brake maintains the desired

lining and puck-to-disc clearance, regardless of lining

or puck wear. See figure 12-47. When you apply the

brakes, hydraulic pressure moves each piston and its

pucks or linings against the disc or discs as applicable.

As the linings wear, the piston pushes against the

adjusting pin (through the spring guide) and moves the

pin against the friction of the adjusting pin grip. When

you release the brake pressure, the force of the return

spring moves the piston away from the brake disc, but

it does not move the adjusting pin, which is held by the

friction of the pin grip. The piston moves away from the

disc until it stops against the head of the adjusting pin.

Thus, regardless of the amount of wear, the same travel

of the piston will be required to apply the brake, and the

running clearance will be maintained.

12-53