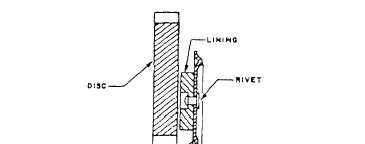

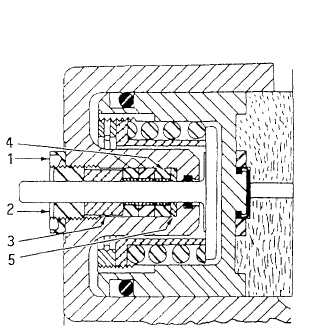

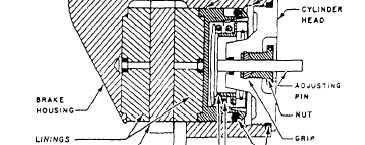

Figure 12–48.—Cross-sectional view of a single disc brake assembly

with captured torquing-type automatic adjuster.

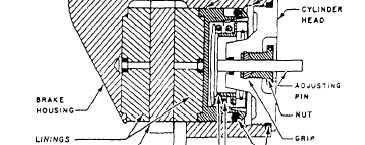

The automatic adjusting feature may be referred to

as a captured torquing type or captured nontorquing

type. Figure 12-48 shows a typical captured

torquing-type automatic adjuster. It is mandatory that

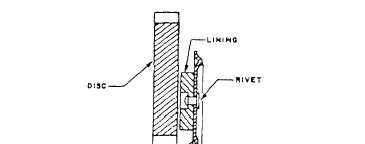

clearance be established between the linings and the

discs before torquing the automatic adjusting nut to the

amount specified for the brake involved. Otherwise, the

brake will drag until an amount equal to the built-in

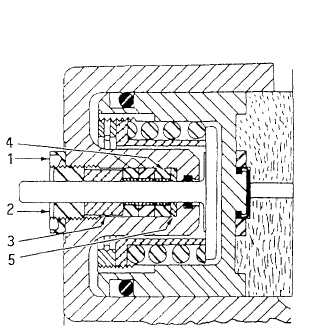

1. Locknut

4. Grips, split collar

2. Threaded bushing

5. Washer

3. Spacer

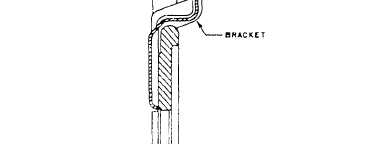

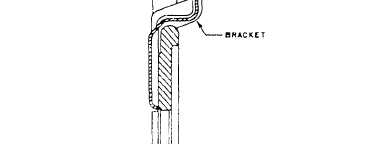

Figure 12-49.—Captured nontorquing-type automatic adjuster.

clearance is worn from the face of the linings. With the

adjusting nuts properly torqued, the friction between the

grip and the adjusting pin is great enough to overcome

the compression of the return spring, and the adjusting

pin will be pulled through the grip only to compensate

for lining wear.

After torquing the automatic adjusting nuts to the

specified value, back them off and retorque several

times. This procedure will ensure proper mating of all

parts and the correct torque on the final assembly.

Figure 12-49 shows the captured nontorquing-type

automatic adjuster used on some single and dual disc

brake assemblies.

Brakes that contain nontorquing adjusters can be

identified by the locknut and threaded bushing over each

adjusting pin. The only difference between the torquing-

and nontorquing-type automatic adjustment is the

method used to restrict the movement of the adjusting

pin. The torquing-type adjustment uses a tapered grip,

and the nontorquing uses one or more l/4-inch-wide

grips composed of brass liners.

12-54