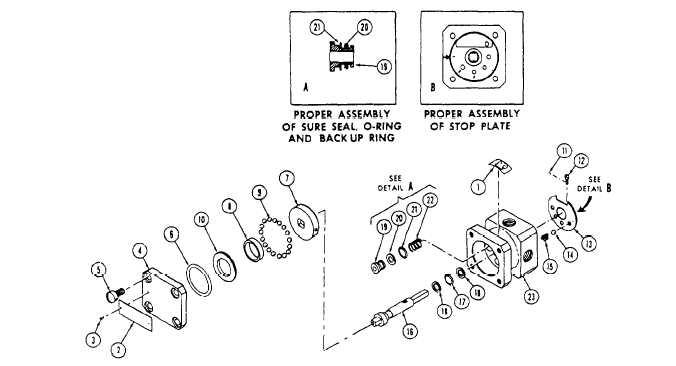

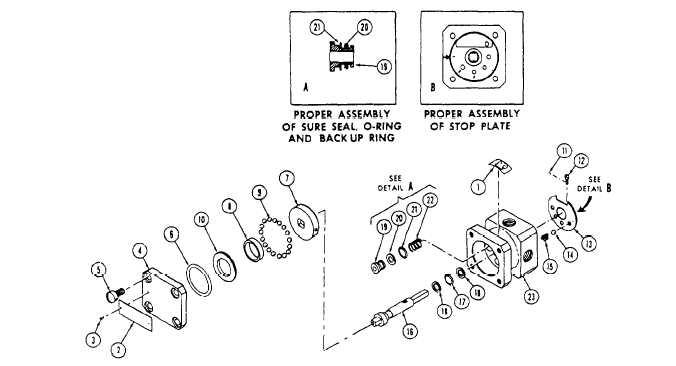

1. Decal

6.

2. Nameplate

7.

3. Drive screw

8.

4. Retainer plate

9.

5. Machine screw 10.

O-ring

11. Thread lock

16. Actuating shaft

21. Backup ring

Shear plate assembly 12. Lock screw

17. O-ring

22. Seal spring

Ball retainer

13. Stop plate

18. Backup ring

23. Body assembly

Balls

14. Ball

19. Sure seal

Bearing plate

15. Detent spring

20. O-ring

Figure 12–45.—Brake selector valve—exploded view.

This procedure completes the thermal crack test. In

preparation for the shuttle valve opening operation test

that follows, block residual pressure in the BRAKE port

using a pressure gauge as the plug.

With the RET port open and BRAKE port capped,

apply hand-pumped hydraulic pressure gradually to the

PMV port. There should be a simultaneous increase of

BRAKE port pressure with PMV port pressure. At a

pressure of 60 to 80 psi in the PMV port, pressure in the

PMV port and BRAKE port should become equal. A

gradual increase in PMV port pressure to 1,500 psi should

result in a proportionate increase in the BRAKE port

pressure. Any displacement at the RET port should not

be considered leakage during this phase of the bench test.

The shuttle valve closing operation test begins with

1,500 psi from the previous phase still applied to the

PMV port. Reduce the pressure at the PMV port to 150

psi, and then rapidly to 0 psi. The closing operation is

evidenced by the venting of hydraulic fluid from the

RET port as PMV pressure decreases from 20 psi to 0 psi.

The final phase of the bench test is the test for

leakage. This phase is started with 27-psi hydraulic

pressure trapped in the BRAKE port. There should be

no evidence of pressure decrease when it is measured

over a period of 3 minutes. Continue the test with the

BRAKE port capped and the RET port of the valve in

an upright position. Fill the RET port cavity and a

leakage measuring device with hydraulic fluid. Apply

hand-pumped hydraulic pressure of 30 to 37 psi to the

PMV port. Leakage at the RET port must not exceed 0.5

cubic centimeter per minute. Immediately after

application of pressure, measure the leakage for a

3-minute period. Disregard volume displacement

because of shuttle valve transition if leakage is not in

excess of 0.5 cubic centimeter per minute. Increase the

pressure to 125 psi and maintain for a 3-minute period.

There should be no evidence of leakage. Further

increase the pressure to 1,500 psi and maintain for

another 3-minute period. There should be no leakage.

BRAKE SELECTOR VALVE

Repair of the brake selector valve at the

intermediate level of maintenance is limited to the

replacement of cure-date items and parts listed under

Spares and Replacement Parts Data in the "Intermediate

Maintenance” section of the MIM.

Figure 12-45 shows an exploded

selector valve. Observe the arrangement

view of the

in which the

12-51