CABLE AND RIGID CONTROL

SYSTEMS RIGGING

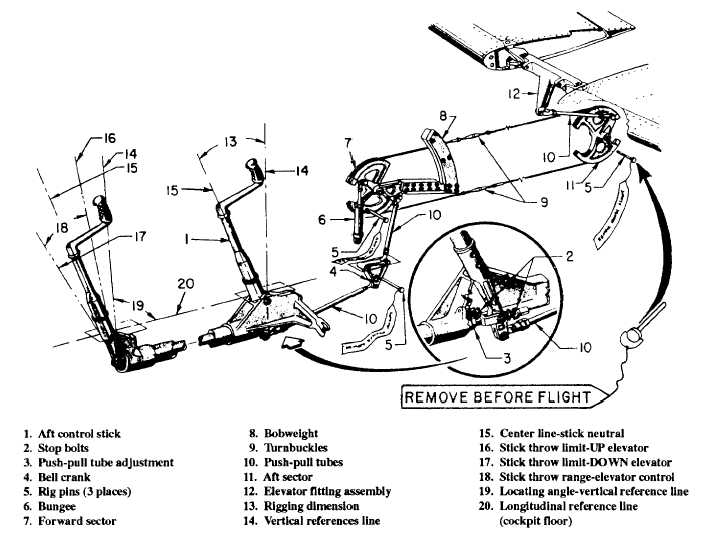

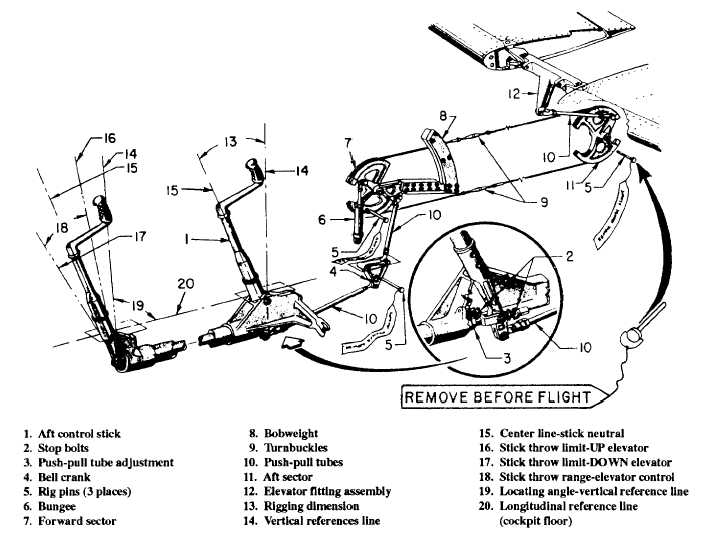

In the elevator system shown in figure 9-26,

rigging begins at the aft sector.

The aircraft

manufacturer has determined the position of the aft

sector when it is in the neutral position. A rig pinhole

has been furnished in the sector and a mating hole in

the adjoining structure.

See the three rig pins in

figure 9-26. With the rig pin inserted in the aft sector

and in the aircraft structure, the sector is held firmly in

the neutral position. With the sector in this position,

the push-pull tube connecting the sector with the

elevator fitting assembly is adjusted to position the

elevators to the neutral position. The neutral position

is determined by using the elevator rigging fixture

shown in figure 9-27.

The curved section of the

rigging fixture is graduated in degrees on either side

of the neutral (zero degree) position that is about

midway on the curved part of the fixture.

The rigging fixture is fastened securely to the

aircraft at the indicated points of attachment. When

properly mounted, the index marks (graduations) on the

curved section align with the elevators and indicate the

position, in degrees, of the elevators. If, with the aft

sector rig pin in place, the elevators are not in neutral

(for example, 5 degrees above the neutral mark),

lengthening the push-pull rod end will push the elevator

fitting assembly forward, and thereby lower the

elevators. If the elevators are too low, then shortening

the rod will bring them up as required.

The next step is the adjusting and tightening of the

pair of cables in the system. This is accomplished by

tightening the turnbuckles on each cable evenly until

the required tension is obtained. During cable

tightening, the rig pin is retained in the aft sector,

leaving the forward sector free to turn. Therefore,

when the necessary tension is recorded on one cable,

that is also the tension on the other cable. To ensure

9-32

Figure 9-26.—Typical elevator flight control system.