CABLE AND RIGID CONTROL

SYSTEMS TROUBLESHOOTING

When the cause and remedy for a reported

malfunction in a control system are not immediately

obvious to you, it maybe necessary to troubleshoot the

system. Most aircraft MIMs provide troubleshooting

charts that list some of the more common malfunctions

in a system. Each discrepancy is accompanied by one

or more probable causes, and a remedy is prescribed for

each cause. The troubleshooting charts are organized in

a definite sequence under each possible trouble,

according to the probability of failure and ease of

investigation. To obtain maximum value from these

charts, they should be used systematically according to

the aircraft manufacturer’s recommendations.

Examples of typical troubleshooting charts and

instructions on their proper use was discussed in chapter

3 of this TRAMAN.

Since most aircraft use some form of electrical

control or hydraulic boost in their flight control systems,

maintenance of these systems must include the related

electrical circuits and hydrauIic systems. Although an

AE or AM is generally called upon to locate the correct

electrical or hydraulic troubles respectively, you should

be able to check circuits for loose connection, perform

continuity checks, and perform minor troubleshooting

of the hydraulic system.

Basically there are seven distinct steps to follow

during troubleshooting. These steps were discussed

in chapter 3 of this TRAMAN.

RIGGING AND ADJUSTING TOOLS

The purpose of rigging and adjusting a primary

flight control system is to ensure neutral alignment of

all connecting components and to regulate and limit

the surface deflection in both directions. Each

aircraft has a set of special tools for flight control

maintenance that may include rigging fixtures, pins,

blocks, throwboards and protractors. Other common

equipment, such as micrometers, pressure gauges,

push-pull gauges, feeler gauges, tensiometer and

calipers may also be required. These arc usually

maintained in the toolroom and checked out when

needed.

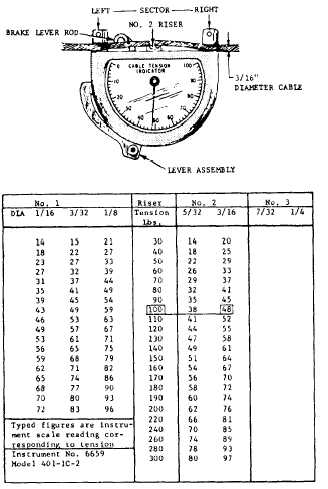

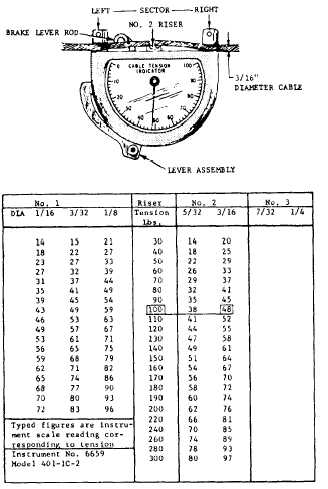

Tensiometer

The tensiometer is an instrument used in checking

cable tension. Tension is the amount of pulling force

applied to the cable. The amount of tension applied in

a cable linkage system is controlled by turnbuckles in

the system.

A tensiometer is a precision cable tension measuring

device, but it has limitations and can be awkward to use.

It is inaccurate for cable tension under 30 pounds. When

you take tension measurements, the instrument must not

be pressed against any part of the aircraft, it can’t be

pushed or pulled against the cable, and the cable must not

be pressed against fairleads or any part of the aircraft.

Any one of these actions may lead to inaccurate

measurements. A major advantage of cable linkage is its

minimal space requirement and the ease in which it can be

routed around, through, and behind aircraft structures and

components. This can make access difficult and the

tensiometer awkward or difficult to use.

Adequate

clearance for the tensiometer is necessary. All

tensiometers must be certified by a calibration laboratory

for accuracy at least once a month.

One type of tensiometer is shown in figure 9-23.

This instrument works on the principle of measuring

Figure 9-23.—Cable tensiometer and chart.

9-29