CABLE

MAINTENANCE.-Cable

~

control

systems require more maintenance than rigid linkage

systems; therefore, they must be inspected more

thoroughly. Cables must be kept clean and inspected

periodically for broken wires, corrosion, kinking, and

excessive wear.

Broken wires are most apt to occur in lengths of

cable that pass over pulleys or through fairleads. On

certain periodic inspections, cables are checked for

broken wires by passing a cloth along the length of the

cable.

Where the cloth snags the cable is an

indication of one or more broken wires.

WmNG

Your bare hands should NEVER be used to

check for broken wires.

Using your bare

hands to check for broken wires could

result in personal injury.

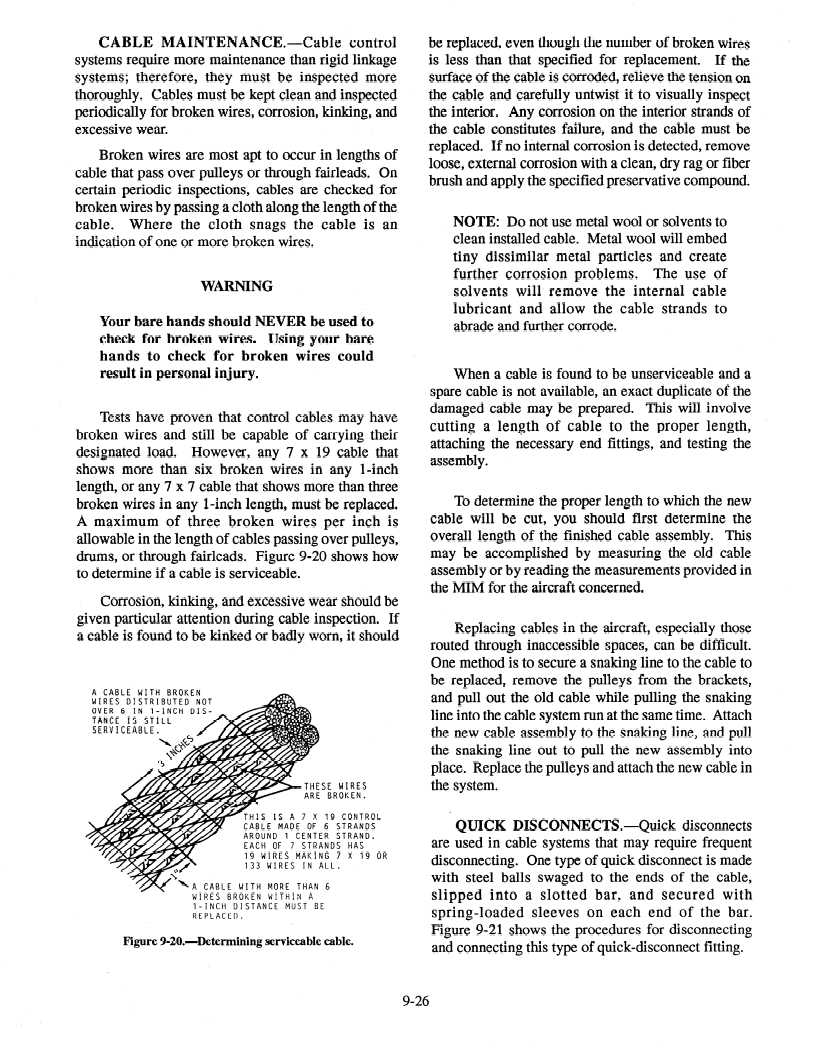

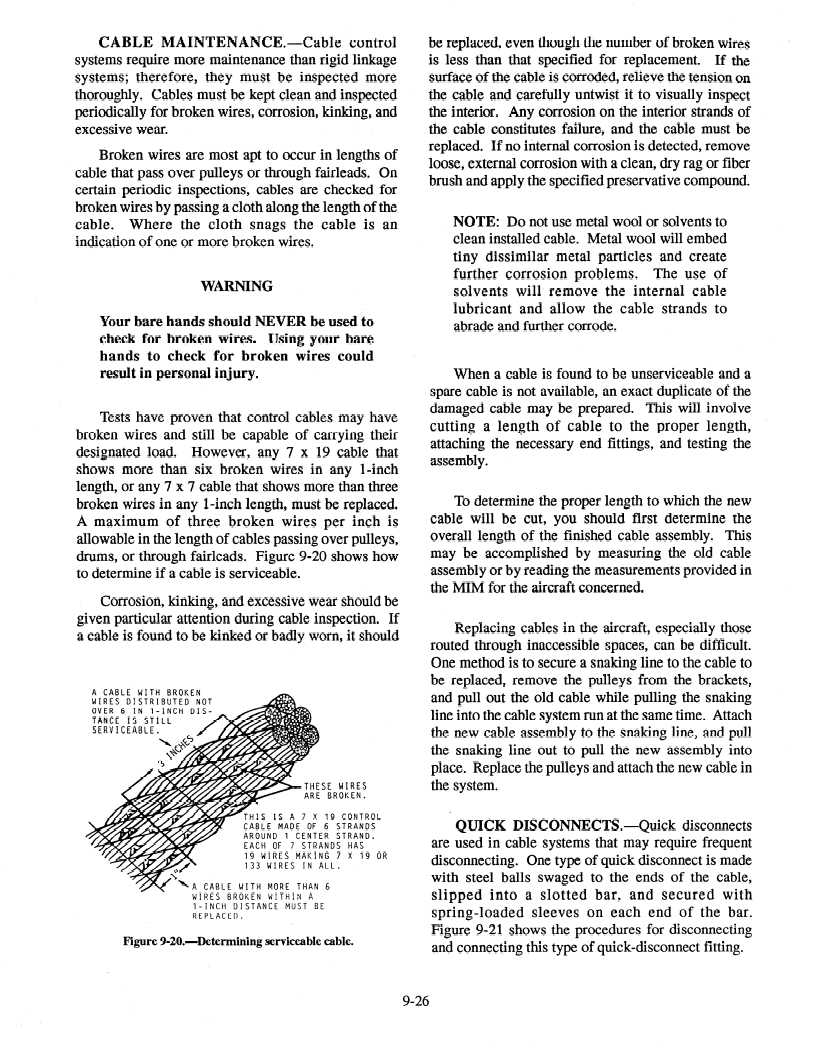

Tests have proven that control cables may have

broken wires and still be capable of carrying their

designated load.

However, any 7 x 19 cable that

shows more than six broken wires in any l-inch

length, or any 7 x 7 cable that shows more than three

broken wires in any l-inch length, must be replaced.

A maximum of three broken wires per inch is

allowable in the length of cables passing over pulleys,

drums, or through fairleads. Figure 9-20 shows how

to determine if a cable is serviceable.

Corrosion, kinking, and excessive wear should be

given particular attention during cable inspection. If

a cable is found to be kinked or badly worn, it should

A

CABLE

WITH

BROKEN

WIRES

DISTRIBUTED

NOT

OVER

6

IN

I-INCH

D

TANCE

IS

STILL

SERVICEABLE.

THESE

WIRES

ARE

BROKEN.

HIS

IS

A

7

X

19

CONTROL

ABLE

MADE

OF

6

STRANOS

AROUND

1

CENTER

STRAND.

EACH

OF

7

STRANDS

HAS

19

WIRES

MAKING

7

X

19

OR

133

WIRES

IN

ALL.

'A

CABLE

WITH

MORE

THAN

6

WIRES

BROKEN

WITHIN

A

I-INCH

DISTANCE

MUST

BE

REPLACED.

Figure 9-20.-Determining

serviceable cable.

be replaced, even though the number of broken wires

is less than that specified for replacement. If the

surface of the cable is corroded, relieve the tension on

the cable and carefully untwist it to visually inspect

the interior. Any corrosion on the interior strands of

the cable constitutes failure, and the cable must be

replaced. If no internal corrosion is detected, remove

loose, external corrosion with a clean, dry rag or fiber

brush and apply the specified preservative compound.

NOTE: Do not use metal wool or solvents to

clean installed cable. Metal wool will embed

tiny dissimilar metal particles and create

further corrosion problems.

The use of

solvents will

remove the internal

cable

lubricant

and allow the cable strands to

abrade and further corrode.

When a cable is found to be unserviceable and a

spare cable is not available, an exact duplicate of the

damaged cable may be prepared. This will involve

cutting a length of cable to the proper length,

attaching the necessary end fittings, and testing the

assembly.

To determine the proper length to which the new

cable will be cut, you should first determine the

overall length of the finished cable assembly. This

may be accomplished by measuring the old cable

assembly or by reading the measurements provided in

the MIM for the aircraft concerned.

Replacing cables in the aircraft, especially those

routed through inaccessible spaces, can be difficult.

One method is to secure a snaking line to the cable to

be replaced, remove the pulleys from the brackets,

and pull out the old cable while pulling the snaking

line into the cable system run at the same time. Attach

the new cable assembly to the snaking line, and pull

the snaking line out to pull the new assembly into

place. Replace the pulleys and attach the new cable in

the system.

QUICK DISCONNECTS.-Quick

disconnects

are used in cable systems that may require frequent

disconnecting. One type of quick disconnect is made

with steel balls swaged to the ends of the cable,

slipped

into a slotted

bar, and secured with

spring-loaded

sleeves on each end of the bar.

Figure 9-21 shows the procedures for disconnecting

and connecting this type of quick-disconnect fitting.

9-26