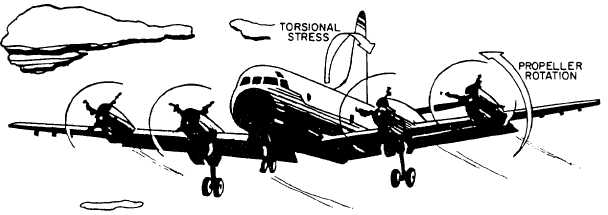

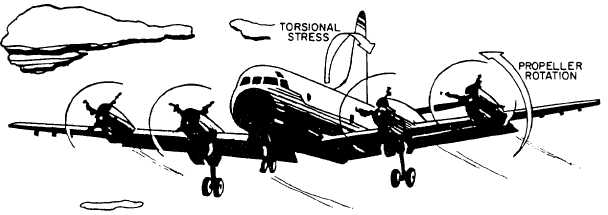

Figure 1-20.—Engine torque creates torsional stress in aircraft fuselages.

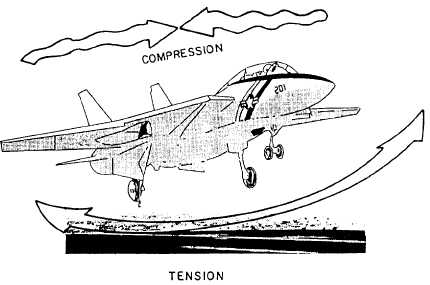

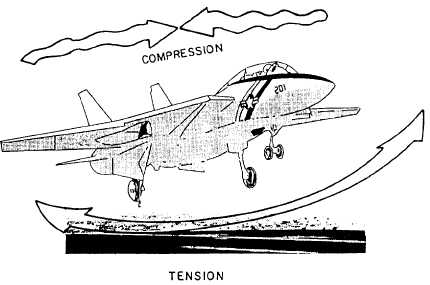

Figure 1-21.—Bending action occurring during carrier landing.

An aircraft requires materials that must be both light

and strong. Early aircraft were made of wood.

Lightweight metal alloys with a strength greater than

wood were developed and used on later aircraft.

Materials currently used in aircraft construction maybe

classified as either metallic or nonmetallic.

COMMON METALLIC MATERIALS

The most common metals in aircraft construction

are aluminum, magnesium, titanium, steel, and their

alloys. Aluminum alloy is widely used in modern

aircraft construction. It is vital to the aviation industry

because the alloy has a high strength-to-weight ratio.

Aluminum alloys are corrosion-resistant and com-

paratively easy to fabricate. The outstanding character-

istic of aluminum is its lightweight.

Magnesium, the world’s lightest structural metal, is

a silvery-white material weighing only two-thirds as

much as aluminum. Magnesium is used in the

manufacture of helicopters. Magnesium’s low

resistance to corrosion has limited its use in con-

ventional aircraft.

Titanium is a lightweight, strong, corrosion-

resistant metal. It was discovered years ago, but only

recently has it been made suitable for use in aircraft.

Recent developments make titanium ideal for

applications where aluminum alloys are too weak and

stainless steel is too heavy. In addition, titanium is

unaffected by long exposure to seawater and marine

atmosphere.

An alloy is composed of two or more metals. The

metal present in the alloy in the largest portion is called

1-21