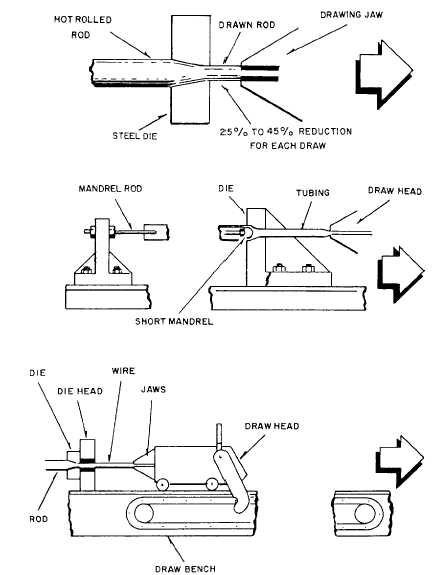

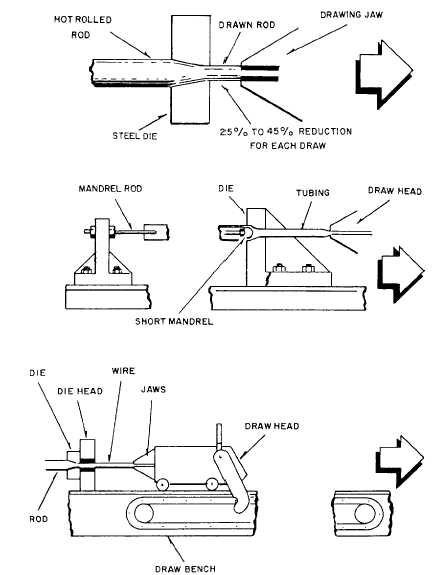

Figure 1-23.—Cold-drawing operations for rod, tubing, and wire.

or bulged. The advantage of hammering is that the

operator has control over the amount of pressure applied

and the finishing temperature, and is able to produce

parts of the highest grade.

This type of forging is usually referred to as smith

forging, and it is used extensively where only a small

number of parts are needed. Considerable machining

and material are saved when a part is smith forged to

approximately the finished shape.

Cold-Working

Cold-working applies to mechanical working

performed at temperatures below the critical range, and

results in a strain hardening of the metal. It becomes so

hard that it is difficult to continue the forming process

without softening the metal by annealing.

Since the errors attending shrinkage are eliminated

in cold-working, a much more compact and better metal

is obtained. The strength and hardness as well as the

elastic limit are increased, but the ductility decreases.

Since this makes the metal more brittle, it must be heated

from time to time during certain operations to remove

the undesirable effects of the working.

While there are several cold-working processes, the

two with which you are principally concerned are

cold-rolling and cold-drawing. These processes give the

metals desirable qualities that cannot be obtained by

hot-working.

1-26