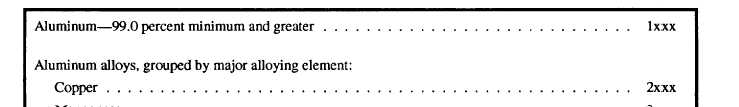

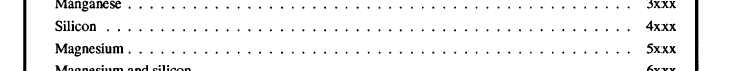

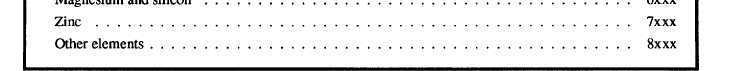

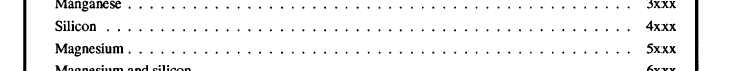

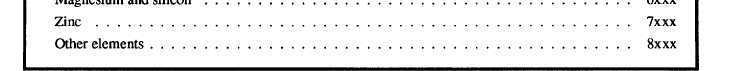

Table 1-2.—Designations for Aluminum Alloy Groups

In the 2xxx through 8xxx groups, the second digit

indicates alloy modifications. If the second digit in the

designation is zero, it indicates the original alloy, while

numbers 1 through 9, assigned consecutively, indicate

alloy modifications. The last two of the four digits have

no special significance, but serve only to identify the

different alloys in the group.

The temper designation follows the alloy

designation and shows the actual condition of the metal.

It is always separated from the alloy designation by a

dash.

The letter F following the alloy designation

indicates the “as fabricated condition, in which no

effort has been made to control the mechanical

properties of the metal,

The letter O indicates dead soft, or annealed,

condition.

The letter W indicates solution heat treated. Solution

heat treatment consists of heating the metal to a high

temperature followed by a rapid quench in cold water,

This in an unstable temper, applicable only to those

alloys that spontaneously age at room temperature,

Alloy 7075 may be ordered in the W condition.

The letter H indicates strain hardened, cold-worked,

hand-drawn, or rolled. Additional digits are added to the

H to indicate the degree of strain hardening. Alloys in

this group cannot be strengthened by heat treatment,

hence the term nonheat-treatable.

The letter T indicates fully heat treated. Digits are

added to the T to indicate certain variations in treatment.

Greater strength is obtainable in the heat-treatable

alloys. They are often used in aircraft in preference to

the nonheat-treatable alloys. Heat-treatable alloys

commonly used in aircraft construction (in order of

increasing strength) are 6061, 6062, 6063, 2017, 2024,

2014,7075, and 7178.

Alloys 6061, 6062, and 6063 are sometimes used

for oxygen and hydraulic lines and in some applications

as extrusions and sheet metal.

Alloy 2017 is used for rivets, stressed-skin

covering, and other structural members.

Alloy 2024 is used for airfoil covering and fittings.

It may be used wherever 2017 is specified, since it is

stronger.

Alloy 2014 is used for extruded shapes and

forgings. This alloy is similar to 2017 and 2024 in that

it contains a high percentage of copper. It is used where

more strength is required than that obtainable from 2017

or 2024.

Alloy 7178 is used where highest strength is

necessary, Alloy 7178 contains a small amount of

chromium as a stabilizing agent, as does alloy 7075.

Nonheat-treatable alloys used in aircraft

construction are 1100, 3003, and 5052. These alloys do

not respond to any heat treatment other than a softening,

annealing effect. They may be hardened only by

cold- working.

Alloy 1100 is used where strength is not an

important factor, but where weight, economy, and

corrosion resistance are desirable. This alloy is used for

1-31