assembly consists of a bobweight, a viscous damper,

and a push-pull tube.

The push-pull tube is the

interconnect between the control stick and the

bobweight. The damper is located at the pivot point

of the bobweight and restricts fast movement of the

bobweight.

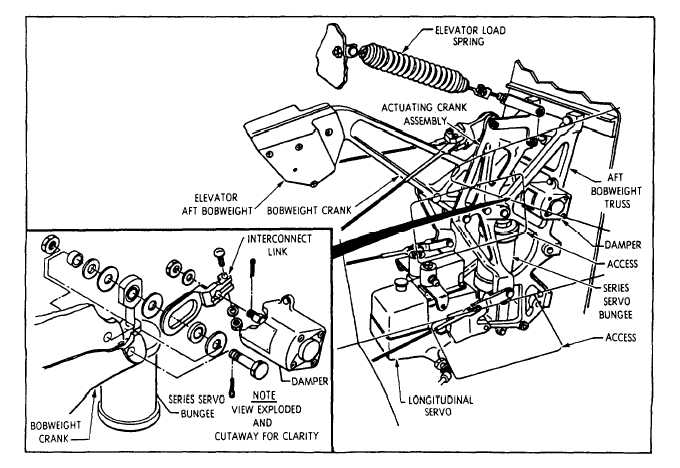

The aft bobweight and damper assembly works

with the forward assembly to overcome the heavy pull

of gravity and retard the chance of overcontrol. See

figure 9-4. This assembly is installed in the fuselage,

forward and below the horizontal stabilizer. It

connects to the elevator control cables.

The aft assembly consists of a bobweight, a

viscous damper, and a load spring. The bobweight

connects to the elevator control bell crank and the

damper. The load spring is between the elevator

control bell crank and the fin structure to balance the

forward and aft bobweights when the elevator is in a

neutral position.

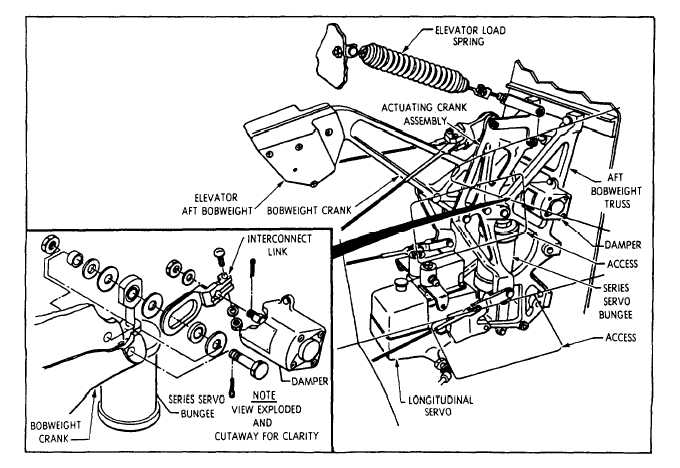

The elevator power mechanism changes the

mechanical movement of the control stick to the

hydraulic operation of the elevator. See figure 9-5.

The mechanism is in the aft section of the aircraft

directly below the horizontal stabilizer. As in the

aileron power system, the mechanism consists of a

hydraulic power cylinder, control valves, linkage, and

hydraulic piping.

When the elevator controls are operated, the

control valves port hydraulic pressure to the power

cylinder. The hydraulic pressure extends or retracts

the cylinder piston to move the push-pull tubes. The

push-pull tubes deflect the elevators. The control

valves are two separate valves connected in tandem

by linkage. One valve is supplied hydraulic pressure

by the utility hydraulic system. The other valve is

supplied hydraulic pressure by the flight control

hydraulic system.

The power cylinder has dual

hydraulic chambers to work from each control valve.

Each hydraulic system simultaneously supplies

Figure 9-4.—Elevator aft bobweight and damper assembly.

9-4