through the shuttle and sleeve assembly. Subsystem

pressurized fluid works on the large flange area of the

shuttle, which causes the shuttle to move to the left

after reaching a specified pressure, thus closing off

the normal system.

The valve will stay in this

position until the subsystem pressure is lowered, at

which time the shuttle will move to its prior position

and allow the required amount of pressurized fluid to

enter the subsystem. During normal operation of the

subsystem, the pressure-reducing valve continuously

meters fluid to the subsystem.

HYDRAULIC FUSES

A hydraulic fuse is a safety device. Fuses may be

installed at strategic locations throughout a hydraulic

system. They are designed to detect line or gauge

rupture, fitting failure, or other leak-producing failure

or damage.

One type of fuse, referred to as the automatic

resetting type, is designed to allow a certain volume

of fluid per minute to pass through it. If the volume

passing through the fuse becomes excessive, the fuse

will close and shut off the flow. When the pressure is

removed from the pressure supply side of the fuse, it

will automatically reset itself to the open position.

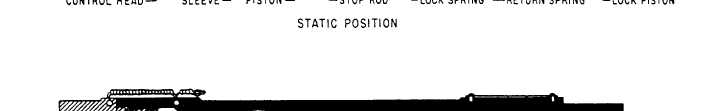

Fuses are usually cylindrical in shape, with an

inlet and outlet port at opposite ends, as shown in

figure 8-18. A stationary sleeve assembly is con-

tained within the body. Other parts contained within

the body, starting at the inlet port, are a control head,

piston and piston subassembly stop rod, a lock spring,

and a lock piston and return spring.

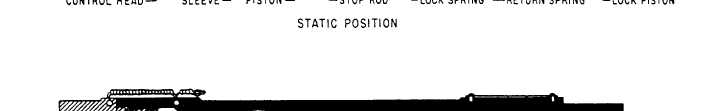

Fluid entering the fuse is divided into two flow

paths by the control head. The main flow is between

the sleeve and body, and a secondary flow is to the

piston. Fluid flowing through the main path exerts a

force on the lock piston, causing it to move away from

the direction of flow, This movement uncovers ports,

allowing fluid to flow through the fuse.

The movement of the locking piston also causes a

lock spring to release the piston subassembly stop

Figure 8-18.—Fuse, operational view.

8-22