One-Way Restrictor

One-way restrictors provide reduced hydraulic

flow in one direction only, to limit actuating speed of

hydraulic cylinders for the purpose of proper timing

or sequence of operation. Also, they provide free

flow of fluid in the opposite direction to permit the

actuating cylinder to actuate at a faster rate of speed

during the reverse action of the cylinder.

One-way restrictors are used in some landing gear

systems to regulate the speed and sequence of landing

gear retraction or extension. If sequenced action (that

is, one cylinder to be actuated before other cylinders

on the same line) is desired, one-way restrictors are

placed in the line upstream of all cylinders except one.

Figure 8-16 shows both the one-way and two-way

restrictors. The main parts of a one- way restrictor are

the cylindrical body and cap, which contain a

spring-loaded poppet, a cage, and a stainless steel

filter element.

The one-way restrictor allows free flow in one

direction and restricted flow in the opposite direction.

Both directions of flow are indicated by arrows found

on the body of the valve.

In a restricted direction, pressurized fluid entering

port R (fig. 8-16) flows through the filter assembly

and enters the cage through drilled passages. Fluid

from the interior of the cage is forced through the

poppet’s orifice, thus causing the required metering

action.

In the free flow direction, pressurized fluid

entering port F overcomes poppet spring tension and

allows fluid to flow past the poppet’s seat, through

drilled passages within the larger flange of the cage,

and out through port R.

Two-Way Restrictor

Two-way restrictors are used to limit the flow of

hydraulic fluid where it is desirable to retard the

action of a hydraulic cylinder in both directions.

Figure 8-16 shows two types of two-way restrictors,

one of which has a machined orifice with two integral

stainless steel filters. The other type shown contains

an orifice plate between two stainless steel filters.

The filters contained within the restrictors are

identical in construction and provide protection in

both directions of flow. The filter size specification

for the two-way restrictor is identical to those found

within one-way restrictors.

Two-way restrictors, regardless of whether they

are of the machined orifice type or of the plate orifice

type, operate identically. Fluid entering either port is

filtered prior to flowing through the orifice, thus

protecting the orifice from possible stoppage. As the

fluid is metered through the orifice, the prescribed

rate flow is directed out the opposite port of the

restrictor and to the actuating unit.

Maintenance of Restrictors

Maintenance of restrictors is usually limited to

checking for external leakage and the required fluid

flow. The specific MIM lists the required fluid flow

in gallons per minute (gpm) for each size of orifice

being checked. It also specifies the correct pressures

to use as well as the required procedures during each

check.

PRESSURE-REDUCING VALVES

Pressure-reducing valves are used in hydraulic

systems where it is necessary to lower the normal

system operating pressure a specified amount.

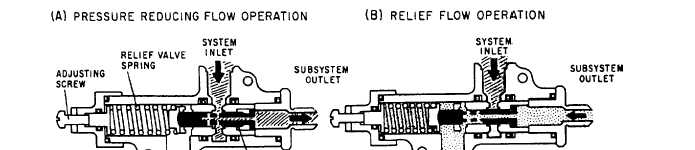

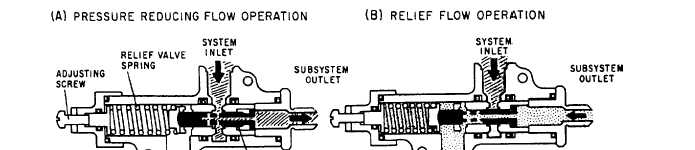

Figure 8-17 shows the operation of a

pressure-reducing valve. View A of figure 8-17

shows system pressure being ported to a subsystem

Figure 8-17.—Pressure-reducing valve operational schematic.

8-21