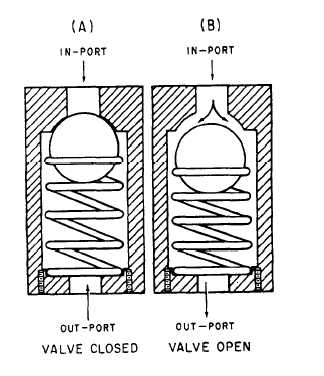

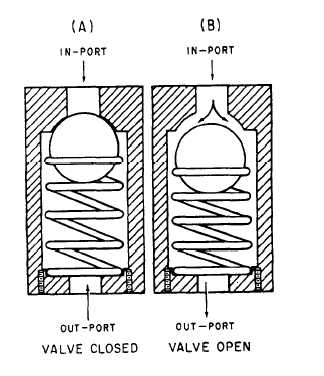

Automatic Check Valves

Automatic check valves contain a seat on which a

movable body (ball, cone, or poppet) seats by means

of spring tension. See figure 8-12. The valve opens

when pressure in the direction of flow (indicated by

an arrow on the body of the valve) is strong enough to

unseat the movable body. Flow in the reverse

direction, along with spring tension, tends to seal the

movable body against the valve seat.

When the pressure on the downstream side of the

valve exceeds that on the upstream side, the resultant

unbalanced force seals the valve closed, as shown in

view A of figure 8-12. When the pressure is reversed,

the valve is forced open against the tension of the

spring, and the fluid flows freely through the valve, as

shown in view B of figure 8-12. The tension of the

spring is relatively weak, and is intended to be barely

sufficient to support the ball in its proper position.

Bypass Check Valves

Bypass check valves serve the same purpose as

automatic check valves, but are so constructed that

they may be opened manually to allow the flow of

fluid in both directions. An example of the possible

use of a bypass check valve is in the line between the

hand pump and the accumulator. Installation of a

Figure 8-12.—Typical check valve.

bypass check valve in this line would allow hand

pump pressure to be directed to either the accumulator

or the selector valve.

Maintenance of Check Valves

Check valves require little attention over long

periods of time.

Leakage may be caused by the

presence of a tiny particle of foreign matter between

the checking device (ball, cone, or poppet) and its

seat. To remove the foreign matter, it is necessary to

remove the valve from the aircraft and completely

disassemble the valve. If no scratches are found on

the valve seat or the checking device, wash all parts in

clean hydraulic fluid of the same type as that used in

the system.

While the valve is disassembled, inspect the

housing and the checking device for evidence of

corrosion. Replace the valve if there is corrosion or

excessive roughness. A slightly rough surface can be

smoothed by buffing. A cone-type check valve may

have a tendency to lean to one side, in which case the

movable part may dig into the soft aluminum body of

the housing and stick there.

When installing a check valve, remember that the

arrow marked on the housing must point in the

direction of the flow of the fluid through the valve.

Before removing a check valve from a line, it is good

practice to mark the adjacent structure, indicating the

direction in which the arrow points. Also, observe the

following precaution during installation of check

valves: Grip the wrench flats of the check valve at the

end to which the connecting tubing is being installed.

Do not grip the opposite end. This will prevent the

possibility of distorting the valve body, causing the

valve to leak.

SEQUENCE VALVES

Sequence valves are used to control a sequence of

operations; they ensure that actuating units operate at

the proper time and in the proper sequence. Sequence

valves may be mechanically operated or

pressure-operated valves. An example of the use of a

sequence valve is in a landing gear actuating system.

In a landing gear actuating system, the landing

gear doors must open before the landing gear starts to

extend. Conversely, the landing gear must be

retracted before the doors close. A sequence valve

installed in each landing gear actuating line performs

this function.

8-16