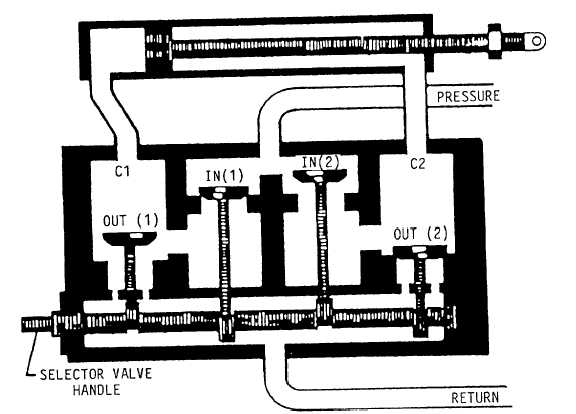

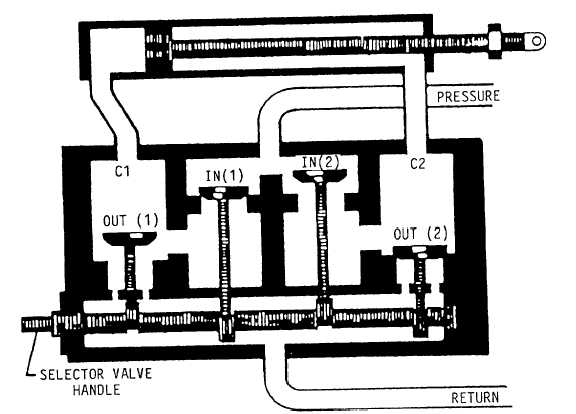

You can rotate the camshaft by moving the

control handle in either direction from neutral. This

action rotates the lobes, which unseat one pressure

poppet and one return poppet. See figure 8-9. The

valve is now in a working position. Pressure fluid,

entering the pressure port, travels through the vertical

fluid passages in both pressure poppet seats. Since

only one pressure poppet is unseated by the cam lobe,

the pressure fluid flows past this open poppet to the

inside of the poppet seat. From there it flows out the

diagonal fluid passages, and then out one cylinder

port and to the actuator.

Return fluid coming from the actuator is coming

in the other cylinder port, through the diagonal fluid

passages, past the unseated return poppet, through the

vertical fluid passages, and out the return port to the

system reservoir. By rotating the camshaft in the

opposite direction until the stop pin hits, the opposite

pressure and return poppets are unseated, and the

fluid flow is reversed. This causes the actuator to

move in the opposite direction.

Selector valves should be checked periodically

for leakage and security of mounting. The operating

linkage should be inspected for ease of operation.

Malfunctioning selector valves are usually the

result of foreign particles or damaged parts. A

malfunctioning valve should be removed and checked

for free movement of the camshaft. The valve maybe

disassembled and all parts cleaned with clean

hydraulic fluid. O-rings should be replaced while the

valve is disassembled.

Both external and internal leakage may be caused

by damaged or worn O-rings. External leakage could

be caused by a damaged gasket under the sealing plug

or the end packing on the camshaft. Internal leakage

could be caused by a damaged center packing on the

camshaft, a damaged bottom gasket on the poppet

seat, or a damaged O-ring packing on the poppet.

NOTE: All selector valves that require repair

or adjustment must be done in accordance

with the applicable MIM or 03 manual. After

repair or adjustment, all valves must be tested

for proper operation and leakage.

Figure 8-9.—Working view of a poppet-type selector valve.

8-11