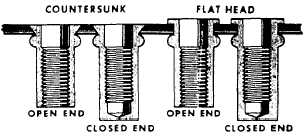

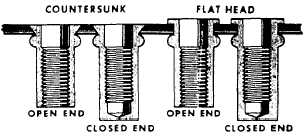

Figure 2-5.—Sectional view of rivnut showing head and end

designs.

Hi-shear rivets are identified by code numbers

similar to the solid rivets. The size of the rivet is

measured in increments of thirty-seconds of an inch

for the diameter and sixteenths of an inch for the grip

length. For example, an NAS 1055-5-7 rivet would be

a hi-shear rivet with a countersunk head. Its diameter

would be 5/32 of an inch and its maximum grip length

would be 7/16 of an inch.

The collars are identified by a basic code number

and a dash number that correspond to the diameter of

the rivet. An A before the dash number indicates an

aluminum alloy collar. The NAS528-A5 collar would

be used on a 5/32-inch-diameter rivet pin. Repair

procedures involving the installation or replacement

of hi-shear rivets generally specify the collar to be

used.

Rivnuts

The rivnut is a hollow rivet made of 6063

aluminum alloy, counterbored and threaded on the

inside. They are manufactured in two head styles, flat

and countersunk, and in two shank designs, open and

closed ends. See figure 2-5. Each of these rivets is

available in three sizes: 6-32, 8-32, and 10-32. These

numbers indicate the nominal diameter and the actual

number of threads per inch of the machine screw that

fits into the rivnut.

Open-end rivnuts are the most widely used, and

are recommended in preference to the closed-end

type. However, in sealed flotation or pressurized

compartments, the closed-end rivnut must be used.

FASTENERS (SPECIAL)

Fasteners on aircraft are designed for many

different functions. Some are made for high-strength

requirements, while others are designed for easy

installation and removal.

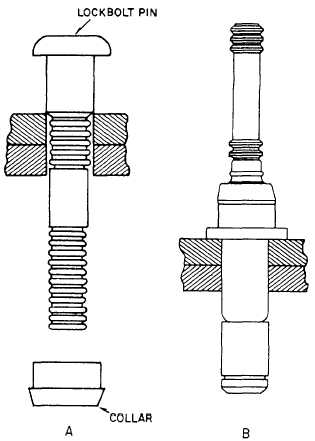

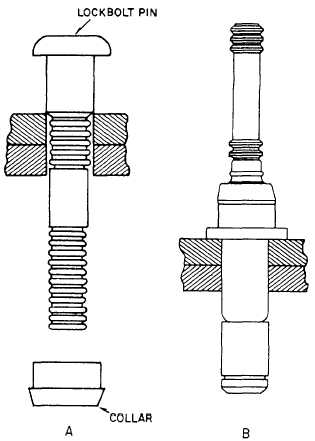

Lock-Bolt Fasteners

Lock-bolt fasteners are designed to meet

high-strength requirements. Used in many structural

applications, their shear and tensile strengths equal or

exceed the requirements of AN and NAS bolts.

The lock-bolt pin, shown in view A of figure 2-6,

consists of a pin and collar. It is available in two head

styles: protruding and countersunk. Pin retention is

accomplished by swaging the collar into the locking

grooves on the pin.

The blind lock bolt, shown in view B of

figure 2-6, is similar to the self-plugging rivet shown

in figure 2-3. It features a positive mechanical leek

for pin retention.

Hi-Lok Fasteners

The hi-lok fastener, shown in figure 2-7, com-

bines the features of a rivet and a bolt and is used for

high-strength, interference-free fit of primary

structures. The hi-lok fastener consists of a threaded

pin and threaded locking collar. The pins are made of

Figure 2-6.—Lock bolts.

2-4