Figure 2-3.—Self-plugging rivet (mechanical lock).

2017-T4 rivet is identified by the raised teat on the

head, while the 2024-T4 has two raised dashes on the

head.

ALLOY 5056 RIVETS.—These rivets are used

primarily for joining magnesium alloy structures

because of their corrosion-resistant qualities. They

are supplied in the H32 temper (strain-hardened and

then stabilized). These rivets are identified by a

raised cross on the head. The 5056-H32 rivet may be

stored indefinitely with no change in its driving

characteristics.

Blind Rivets

In places accessible from only one side or where

space on one side is too restricted to properly use a

bucking bar, blind rivets are usually used. Blind

rivets may also be used to secure nonstructural parts

to the airframe.

Figure 2-3 shows a blind rivet that uses a mechanical

lock between the head of the rivet and the pull stem. Note

in view B that the collar that is attached to the head has

been driven into the head and has assumed a wedge or

cone shape around the groove in the pin. This holds the

shank firmly in place from the head side.

The self-plugging rivet is made of 5056-H14

aluminum alloy and includes the conical recess and

locking collar in the rivet head. The stem is made of

2024-T36 aluminum alloy. Pull grooves that fit into

the jaws of the rivet gun are provided on the stem end

that protrudes above the rivet head. The blind end

portion of the stem incorporates a head and a land (the

raised portion of the grooved surface) with an

extruding angle that expands the rivet shank.

Applied loads for self-plugging rivets are

comparable to those for solid shank rivets of the same

shear strength, regardless of sheet thickness. The

composite shear strength of the 5056-H14 shank and

the 2024-T36 pin exceeds 38,000 psi. Their tensile

strength is in excess of 28,000 psi, Pin retention

characteristics are excellent in these rivets. The

possibility of the pin working out is minimized by the

lock formed in the rivet head.

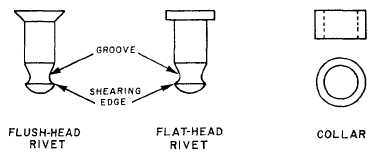

Hi-Shear Rivets

Hi-shear (pin) rivets are essentially threadless

bolts. The pin is headed at one end and is grooved

about the circumference at the other. A metal collar is

swaged onto the grooved end. They are available in

two head styles—the flat protruding head and the

flush 100-degree countersunk head. Hi-shear rivets

are made in a variety of materials, and are used only

in shear applications. Because the shear strength of

the rivet is greater than either the shear or bearing

strength of sheet aluminum alloys, they are used

primarily to rivet thick gauge sheets together. They

are never used where the grip length is less than

the shank diameter. Hi-shear rivets are shown in

figure 2-4.

Figure 2-4.—Hi-shear rivet.

2-3