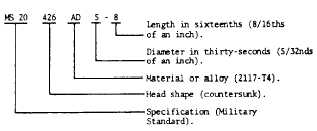

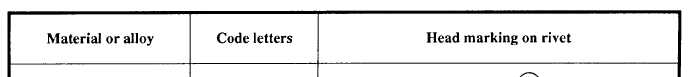

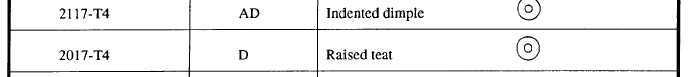

A letter or letters following the head-shaped code

identify the material or alloy from which the rivet was

made. Table 2-1 includes a listing of the most

common of these codes. The alloy code is followed

by two numbers separated by a dash. The first

number is the numerator of a fraction, which specifies

the shank diameter in thirty-seconds of an inch. The

second number is the numerator of a fraction in

sixteenths of an inch, and identifies the length of the

rivet. The rivet code is shown in figure 2-2.

Rivet Composition

Most of the rivets used in aircraft construction are

made of aluminum alloy. A few special-purpose

rivets are made of mild steel, Monel, titanium, and

copper. Those aluminum alloy rivets made of 1100,

2117, 2017,2024, and 5056 are considered standard.

ALLOY 1100 RIVETS.—Alloy 1100 rivets are

supplied as fabricated (F) temper, and are driven in

this condition. No further treatment of the rivet is

required before use, and the rivet’s properties do not

change with prolonged periods of storage. They are

relatively soft and easy to drive. The cold work

resulting from driving increases their strength

slightly. The 1100-F rivets are used only for riveting

nonstructural parts.

These rivets are identified by

their plain head, as shown in table 2-1.

ALLOY 2117 RIVETS.—Like the 1100-F rivets,

these rivets need no further treatment before use and

can be stored indefinitely. They are furnished in the

solution-heat-treated (T4) temper, but change to the

Figure 2-2.—Rivet coding example.

solution-heat-treated and cold-worked (T3) temper

after driving. The 2117-T4 rivet is in general use

throughout aircraft structures, and is by far the most

widely used rivet, especially in repair work. In most

cases the 2117-T4 rivet may be substituted for

2017-T4 and 2024-T4 rivets for repair work by using

a rivet with the next larger diameter. This is desirable

since both the 2017-T4 and 2024-T4 rivets must be

heat treated before they are used or kept in cold

storage. The 2117-T4 rivets are identified by a

dimple in the head.

ALLOY 2017 AND 2024 RIVETS.—As

mentioned in the preceding paragraph, both these

rivets are supplied in the T4 temper and must be heat

treated. These rivets must be driven within 20

minutes after quenching or refrigerated at or below

32°F to delay the aging time 24 hours. If either time

is exceeded, reheat treatment is required. These rivets

may be reheated as many times as desired, provided

the proper solution heat-treatment temperature is not

exceeded. The 2024-T4 rivets are stronger than the

2017-T4 and are, therefore, harder to drive. The

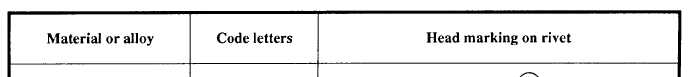

Table 2-1.—Rivet Material Identification

2-2