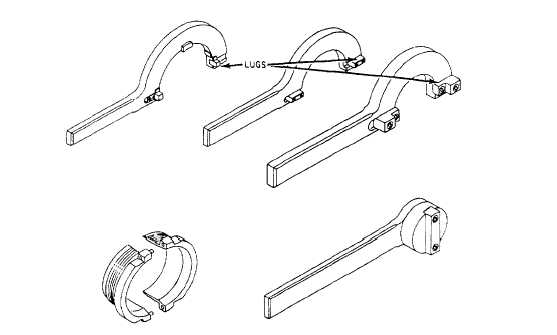

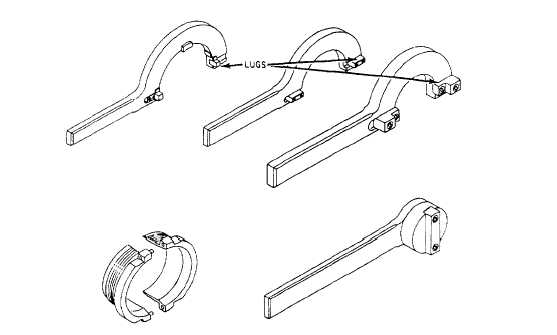

Figure 12-21.-Landing gear shock strut tools.

nut and reinflating the strut, the strut must be dis-

assembled and the packings replaced.

The tools shown in figure 12-21 are typical of the

tools used during disassembly and assembly of landing

gear shock struts. Normally, each tool is designed for,

and should be used only on, one type of installation.

When using wrenches, you must take care to maintain

the lugs of the wrenches in their respective positions.

Slippage of the wrench, when under torquing

conditions, may cause damage to aircraft parts, the tool,

or even injury to personnel. NEVER place extension

handles of any type on these tools to increase the applied

force.

These tools, like other special tools, should be kept

where they will not be subjected to rough handling,

which could cause mushroomed or deformed surfaces,

making them useless for aircraft repair. Shock strut

disassembly and replacement of packings is a

requirement for advancement to first class; therefore, it

is not covered in this training manual.

INTERMEDIATE MAINTENANCE REPAIR

AND SEAL REPLACEMENT

Repair of recoil struts at the intermediate level of

maintenance is restricted to seal replacement and

replacement of parts listed in the “Intermediate

Maintenance Section” of the aircraft MIM or the

appropriate 03 manual. The following paragraphs

provide information on the disassembly, cleaning,

inspection, parts replacement, reassembly, and bench

testing of a strut at the intermediate level.

Disassembly

Disassemble the

key index numbers

strut assembly in the order of the

assigned to the exploded view

illustration provided in the appropriate 03 series

accessories manual or the “Intermediate Maintenance

Section” of the applicable MIM.

WARNING

Before beginning disassembly, make sure

that all pressure has been exhausted from the

strut. Do not disassemble the inner and outer

cylinder until all the pressure has been

released from the strut. Disassembly of the

strut before releasing all pressure could lead

to serious personnel injury or loss of life.

Remove the complete air valve assembly by

breaking the lockwire and unscrewing the 3/4-inch hex

nut. Turn the strut over and drain the hydraulic fluid.

Disconnect the torque arms (scissors). Break the

lockwire and unscrew the packing nut at the bottom of

12-26