BEND

1 TANGENT

(BL) \

MOLD LINE

MOLD POINT

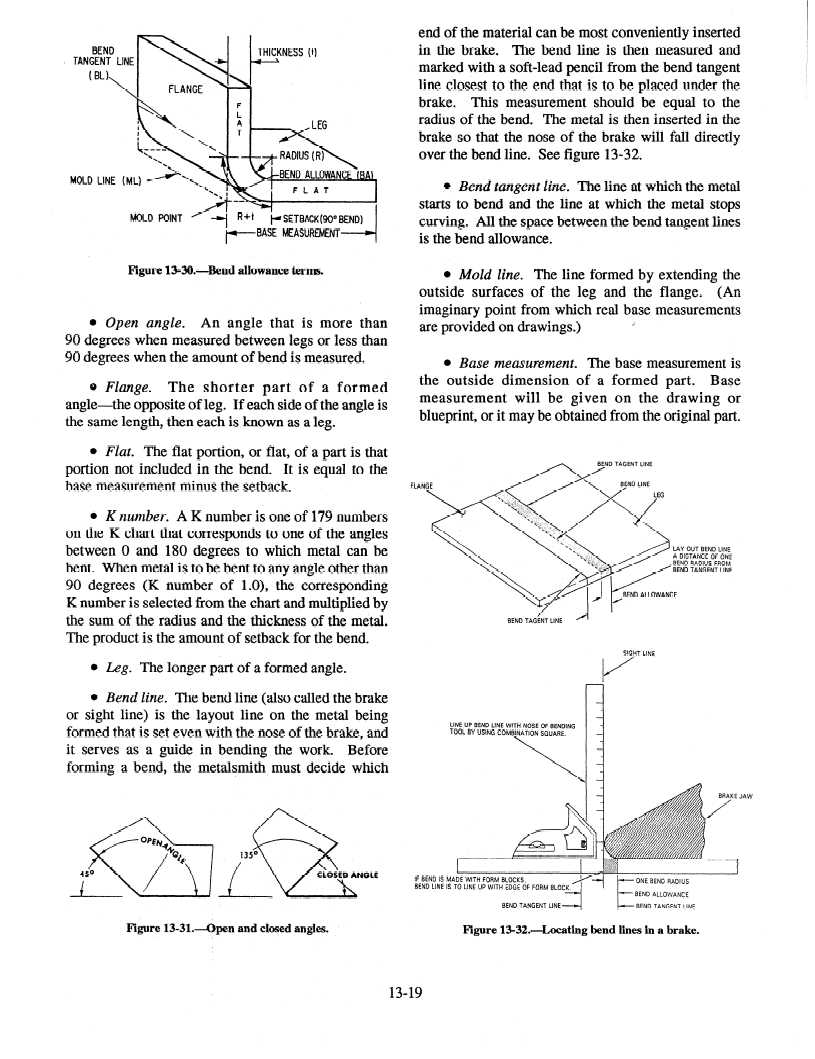

Figure 13-30.~Bend allowance terms.

l

Open angle.

An angle that is more than

90 degrees when measured between legs or less than

90 degrees when the amount of bend is measured.

8 Flange.

The shorter

part

of a formed

angle-the opposite of leg. If each side of the angle is

the same length, then each is known as a leg.

* Flat. The flat portion, or flat, of a part is that

portion not included in the bend. It is equal to the

base measurement minus the setback.

l K number. A K number is one of 179 numbers

on the K chart that corresponds to one of the angles

between 0 and 180 degrees to which metal can be

bent. When metal is to be bent to any angle other than

90 degrees (K number of l.O), the corresponding

K number is selected from the chart and multiplied by

the sum of the radius and the thickness of the metal.

The product is the amount of setback for the bend.

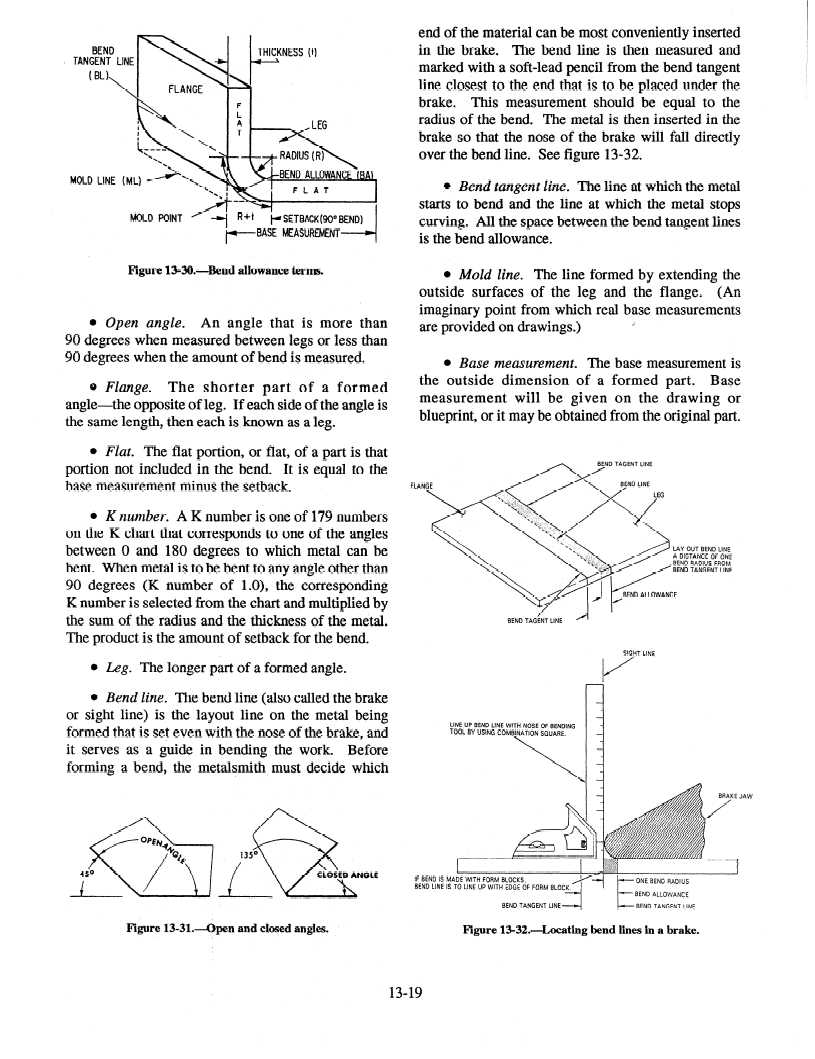

end of the material can be most conveniently inserted

in the brake.

The bend line is then measured and

marked with a soft-lead pencil from the bend tangent

line closest to the end that is to be placed under the

brake.

This measurement should be equal to the

radius of the bend. The metal is then inserted in the

brake so that the nose of the brake will fall directly

over the bend line. See figure 13-32.

l Bend tangent line. The line at which the metal

starts to bend and the line at which the metal stops

curving. All the space between the bend tangent lines

is the bend allowance.

@ MuZd line. The line formed by extending the

outside surfaces of the leg and the flange.

(An

imaginary point from which real base measurements

are provided on drawings.)

l Base measurement. The base measurement is

the outside dimension

of a formed part.

Base

measurement

will

be given on the drawing

or

blueprint, or it may be obtained from the original part.

FL

BEND TAG&T

LINE

/I

SIGHT LINE

l Leg. The longer part of a formed angle.

l Bend line. The bend line (also called the brake

or sight line) is the layout line on the metal being

formed that is set even with the nose of the brake, and

it serves as a guide in bending the work.

Before

forming a bend, the metalsmith must decide which

Figure 13.31.-Open and closed angles.

LINE UP BEND LINE WlTii

NOSE OF BENDING

TOOL BY USING COMBINATION

SQUARE.

I

IF BEND iS MADE WITH FORM BLOCKS.

ONE BEND RADIUS

BEND ALLOWANCE

BEND TANGENT

LINE

BEND TANGENT

LINE

Figure 1%32.4ocating

bend lines in a brake,

13-19