Figure 13-26.—Finger secured in box and pan brake.

Forming Machines

A sheet metal object made on a brake will have

corners (bends) and sides (flanges). On a forming

machine, it is possible to make an object without

sides. For example, you can make a circular object

such as a funnel. The forming machines used in the

Navy are usually located at aircraft intermediate

maintenance departments (AIMDs). The two most

common machines are the slip roll and the rotary.

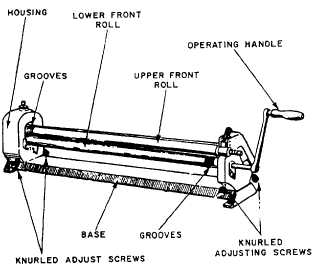

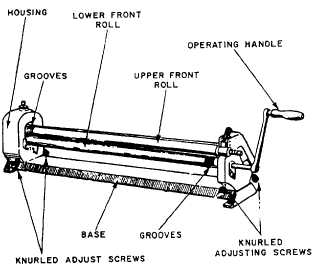

SLIP-ROLL FORMING MACHINE.—Sheet

metal can be formed into curved shapes over a pipe or

a mandrel, but the slip-roll forming machine is easier

to use and produces more accurate bends. Rolling

machines are available in various sizes and capacities.

Some are hand operated, like the one shown in

figure 13-27, and others are power operated.

The machine shown in the illustration has two

rolls in the front and one roll at the rear. You can

adjust screws on each end of the machine to control

Figure 13-27.—Slip-roll forming machine.

the distance between the front rolls. By varying the

adjustments, the machine can be used to form

cylinders, cones, and other curved shapes. The front

rolls grip the metal and pull it into the machine;

therefore, the adjustment of distance between the two

front rolls is made on the basis of the thickness of the

sheet being worked.

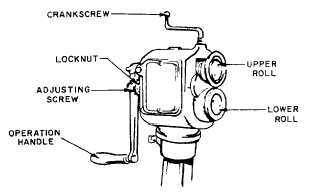

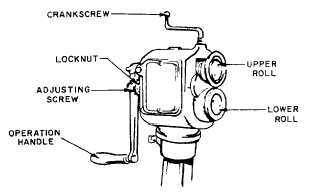

ROTARY MACHINE.—The rotary machine,

shown in figure 13-28, is used on cylindrical and flat

sheet metal to shape the edge or to form a bead along

the edge. Various shaped rolls can be installed on the

rotary machine to perform these operations, which are

described later in the text.

SHEET METAL FABRICATION

Learning Objective: Recognize the terms and

procedures for the fabrication of sheet metal

parts.

To effectively construct and repair parts of an

airframe, you must be able to lay out, cut, and form

metal. The layout of bend lines must include the

allowance for the amount of material used to make the

bend in the proper location. The proper fit of the

finished part can be ensured if the layout, cuts, and

bends are carefully considered before the actual

fabrication is started. The procedures and equipment

discussed in this chapter are designed to provide

accurate and dependable results.

The development of a layout on sheet metal is

basically the same as the development of blueprints

and drawings. For a better understanding of these

procedures, you should refer to Blueprint Reading

and Sketching, NAVEDTRA 1OO77-F1.

Figure 13-28.—Rotary machine.

13-17