217.28

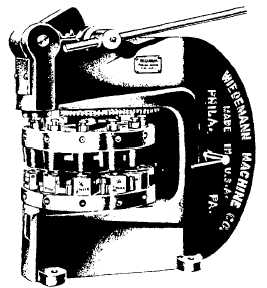

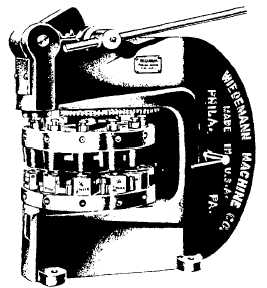

Figure 13-20.—Hand-operated turret punch.

Hand-Operated Turret Punch

A hand-operated turret punch is shown in

figure 13-20. Twelve mated punches and dies are

mounted in a rotating turret. Stamped on the front of

each die block is the size of hole it will punch, as well

as the thickness of the material it will accommodate.

When you are punching stainless steel or other alloys,

you must remember that these capacities are for mild

steel.

The operation of the turret punch is simple. First,

release the locking handle on the side of the punch

frame, rotate the turret until the desired punch set is

lined up with the actuating mechanism (ram), and

then lock the turret into position. Then punch the hole

by pulling the operating lever toward you. This

actuates the ram and punch.

Sheet Metal Bending Equipment

There are a several types of sheet metal bending

equipment that are used to form or bend sheet metal.

In the following text, we will discuss the function of

this equipment.

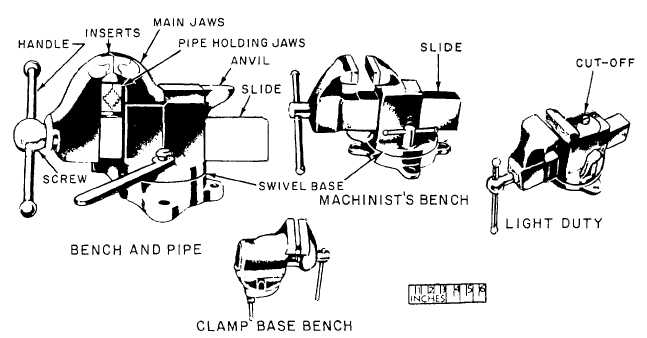

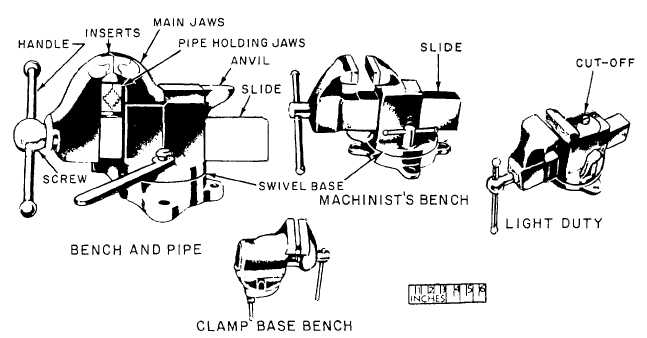

VISE.—Vises are used for holding sheet metal

when it is being shaped or riveted. Figure 13-21

shows the most common bench vises that are used

throughout the Navy. The machinist’s bench vise is

the one most generally used for forming sheet metal.

The machinist’s bench vise is a large steel vise with

rough jaws that prevent the work from slipping. It has

a swivel base, allowing the user to position the vise in

Figure 13-21.—Common types of bench vises.

13-14