prevents loss of hydraulic fluid in the event of utility

or normal system rupture.

As a minimum requirement, filters are provided in

each system pressure line, return line, and pump bypass or

case drain line. Where hydraulic sequencing is critical,

each sequence valve is protected from contamination in

each direction of flow by a screen-type filter. The filter is

usually included as a part of the sequence valve. The

pressure line falters clean all fluids before they enter any

major equipment. If there are only two hydraulic systems,

the primary system is known as the No. 1 power control

system (PC-1). The system supplying the other half of the

flight control tandem actuating mechanisms and the utility

hydraulic system is known as PC-2. The PC-2 system is

also known as the combined hydraulic system. If there are

three hydraulic power systems, they are generally identified

as PC-1, PC-2, and utility system. Some manufacturers

label the utility system PC-3. Each system has its own

reservoir, hydraulic pump(s), and plumbing.

Military specifications, MIL-H-5440 (series),

provide complete design, installation, and data

requirements for aircraft hydraulic systems. These

specifications provide reference to all other specifications

concerning aircraft hydraulic systems. Items such as hose

assemblies, hose support requirements, minimum bend

radii, types of pumps, and types and classes of systems are

found in the specifications.

Many maintenance instruction manuals (MIMs)

refer to aircraft hydraulic systems as being open

center or closed center systems. The following

paragraphs provide a discussion of these systems.

Open Center

An open center system is one having fluid flow, but

no pressure in the system when the actuating mechanisms

are idle. The pump circulates the fluid from the reservoir,

through the selector valves, and back to the reservoir.

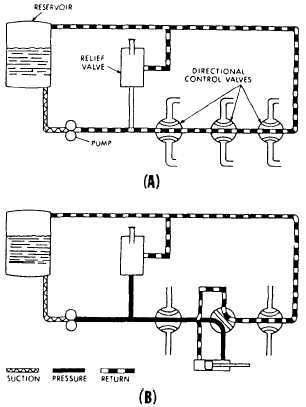

Figure 7-1 shows a basic open center system. The open

center system may employ any number of subsystems,

with a selector valve for each subsystem. Unlike the

closed center system, the selector valves of the open

center system are always connected in series with each

other. In this arrangement, the system pressure line goes

through each selector valve, Fluid is always allowed free

passage through each selector valve and back to the

reservoir until one of the selector valves is positioned to

operate a mechanism.

When one of the selector valves is positioned to

operate an actuating device, fluid is directed from the

pump through one of the working lines to the actuator.

See view B of figure 7-1. With the selector valve in

this position, the flow of fluid through the valve to the

reservoir is blocked. The pressure builds up in the

system to overcome the resistance and moves the

piston of the actuating cylinder, The fluid from the

opposite end of the actuator returns to the selector

valve and flows back to the reservoir. Operation of

the system following actuation of the component

depends on the type of selector valve being used.

Several types of selector valves are used in conjunction

with the open center system. One type is both manually

engaged and manually disengaged. First the valve is

manually moved to an operating position. Then, the

actuating mechanism reaches the end of its operating cycle,

and the pump output continues until the system relief valve

relieves the pressure. The relief valve unseats and allows

the fluid to flow back to the reservoir. The system pressure

remains at the relief valve set pressure until the selector

valve is manually returned to the neutral position. This

action reopens the open center flow and allows the system

pressure to drop to line resistance pressure.

The manually engaged and pressure disengaged

type of selector valve is similar to the valve pre-

viously discussed.

When the actuating mechanism

reaches the end of its cycle, the pressure continues to

rise to a predetermined pressure. The valve auto-

matically returns to the neutral position and to open

center flow.

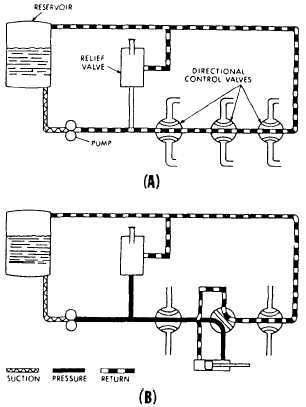

Closed Center

In the closed center system, the fluid is under

pressure whenever the power pump is operating.

Figure 7-2 shows a complex closed center system.

Figure 7-1.—Basic open center hydraulic system.

7-2