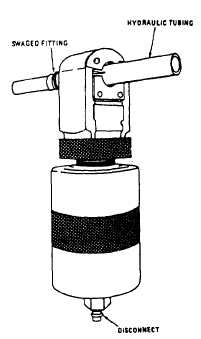

Figure 6-29.—Series D12200 kit swage tool operation.

As a supplement to the series D10000 tool kits,

the series D12200 tool kits (fig. 6-29) may be used.

The newer type of tooling is smaller in size and is

designed to repair tubing on board aircraft.

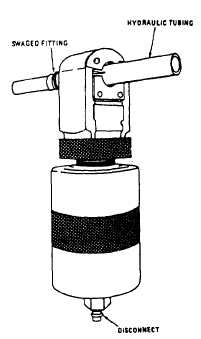

The portable hydraulic power supply D10004

(fig. 6-27) generates 5,500 psi to operate the swaging

tool. Hydraulic fluid is fed to the tool through a

1/4-inch quick-disconnect, high-pressure hose. As a

precaution against premature tool fatigue, the

swaging pressure is kept from exceeding 5,500 psi by

the pressure relief valve. The D 10004 hydraulic

power supply can be operated either manually by

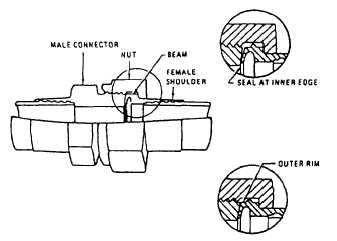

Figure 6-30.—Dynatube fitting.

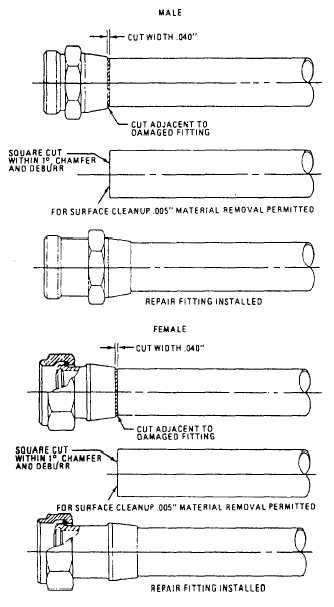

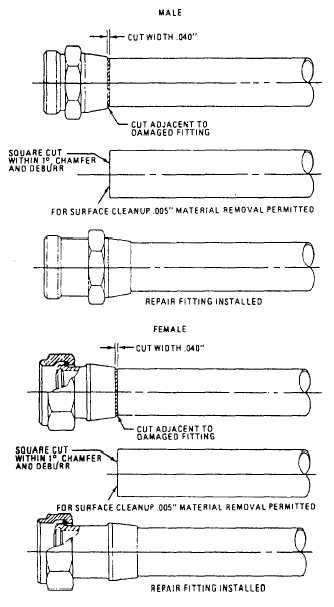

Figure 6-31.—Male and female repair fitting installation.

using a hand pump or automatically by

air-to-hydraulic fluid intensification from a 80 ±20 psi

pressure shop air source.

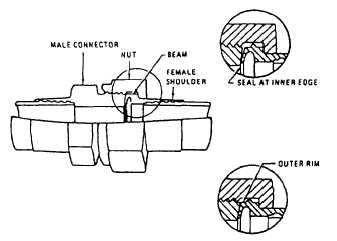

Dynatube Fitting Repair

Dynatube fittings consist of a threaded male

connector, a female shoulder with a machined beam,

and a nut (fig. 6-30). Compared to the five

components in a standard MS fitting, the three

components in a Dynatube fitting are smaller, lighter,

and have fewer potential leak paths. Dynatube

fittings can be connected to rigid tubing by welding,

but internal mechanical swaging with Resistoflex

6-28