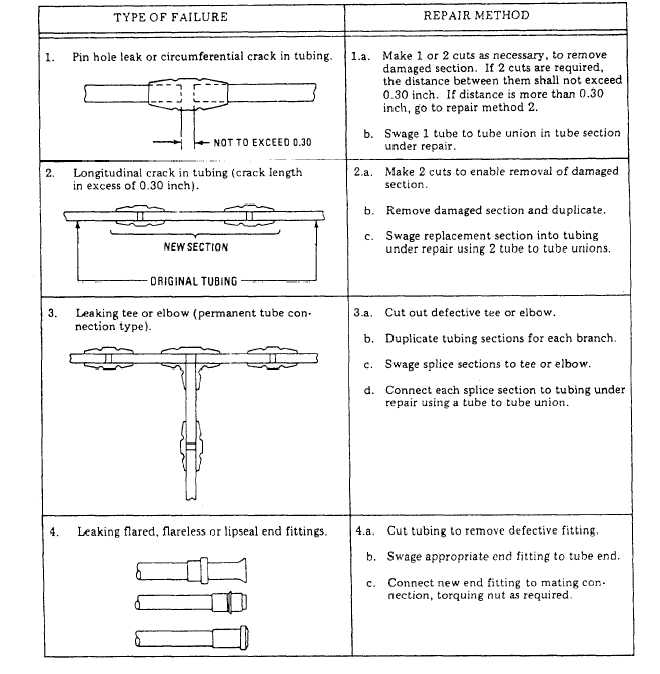

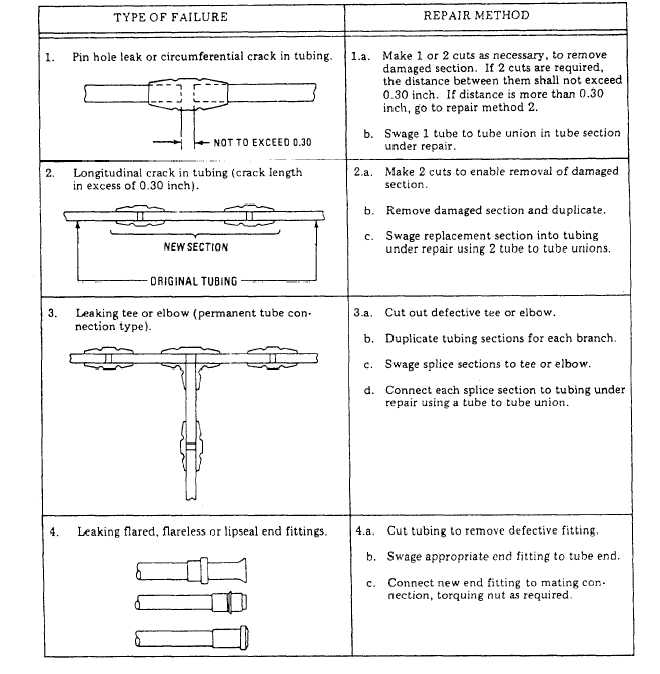

Table 6-11.—Tube Assembly Failures and Recommended Repair Methods

fine file, leaving no file marks, as shown in view C

Permaswage Fitting Repair

of figure 6-24.

Resurface the 37-degree sealing

The basic element of the Permaswage repair techni-

surface. A minimum distance of 1/16 inch (.063)

que is the Permaswage fitting, which is mechanically

should be maintained between the 37-degree

swaged onto the tube by a hydraulically operated tool.

sealing surface and the start of the first thread (view

Permaswage fittings are designed for use by all levels

E of fig. 6-24).

of maintenance, and are available in various configura-

tions. Tube assembly repair using Permaswage fittings

and techniques is considered permanent repair.

All reworked fittings should be inspected and

Four basic types of tube assembly failures lend

treated against corrosion. Reworked aluminum alloy

themselves to permanent repair using Permaswage

fittings and techniques. Each type of tube assembly

fittings should be anodized; however, uniform color

failure and its recommended repair is described in

of reworked fittings after anodizing is not necessary.

table 6-11.

6-25