bulk tubing and fittings before and during fabrication

of a tube assembly. Before replacing a defective tube

assembly, find the cause of failure, and inspect the

tube assembly before and after its installation.

Inspect in-service tube assemblies at regular intervals

in accordance with applicable maintenance directives.

When you inspect the tube and tube assemblies for

damage, look for chafing, galling, or fretting, which

may reduce the ability of tubing to withstand internal

pressure and vibration.

Replace tubing that shows

visible penetration of the tube wall surface caused by

chafing, galling, or fretting. Tubes that have damage

(nicks, scratches, or dents) caused by careless

handling of tools are acceptable if they meet the

following requirements: Any dent that has a depth

less than 20 percent of the tubing diameter is

acceptable unless the dent is on the heel of a short

bend radius. A nick or scratch that has a depth of less

than 15 percent of the wall thickness of aluminum,

aluminum alloy, or steel tubing should be reworked

by burnishing with hand tools before it is acceptable.

Any aluminum, aluminum alloy, or steel tubing

carrying pressures greater than 100 psi with nicks or

scratches greater than 15 percent of wall thickness

should be replaced.

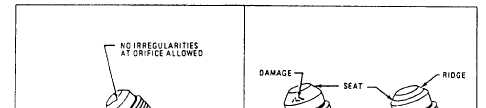

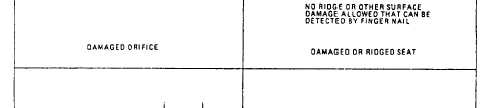

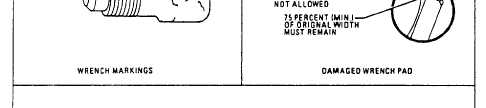

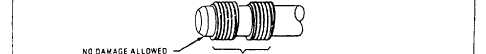

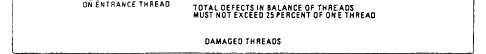

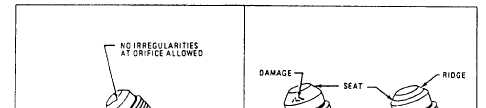

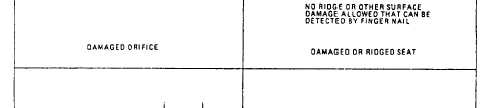

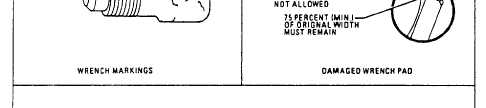

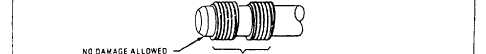

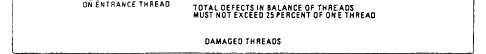

Inspect each fitting (fig. 6-20) before it is

installed. Visually or flow check to make sure that

fitting passage or passages are free from obstructions.

Figure 6-20.—Damaged fittings.

6-20