Figure 6-17.—Fluid line identification application.

stainless steel tubing currently installed on naval

aircraft need not be removed. The basic reason for

this is that cracked or damaged paint systems

establish a differential oxygen concentration cell,

which may result in tubing corrosion damage.

Do not paint interior surfaces of airspeed

indicator tubing, oxygen, or other plumbing lines.

Tube assemblies located inside of an aircraft are

interior tube assemblies. Tube assemblies located

outside of an aircraft are exterior tube assemblies.

Interior tube assemblies require a protective finish of

two coats of zinc chromate, using application

techniques as specified in Aircraft Weapons System

Cleaning and Corrosion Control, NA 01-1A-509.

Protective finishes for exterior tube assemblies should

be the same as for exterior aircraft surfaces specified

in NA01-1A-509.

and all others where tapes should not be used, painted

identification is applied to the lines.

Identification tape codes indicate the function,

contents, hazards, direction of flow, and pressure in

the fluid line. These tapes are applied in accordance

with MIL-STD-1247C. This military standard was

issued to standardize fluid line identification

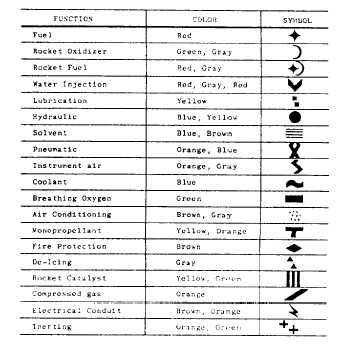

throughout the Department of Defense. Figure 6-17

shows the method of applying these tapes as specified

by this standard.

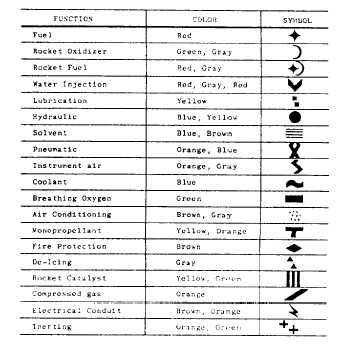

The function of a line is identified by use of a

tape, approximately 1 inch wide, upon which word(s),

color(s), and geometric symbols are printed.

Functional identification markings, as provided in

MIL-STD-1247C, are the subject of international

standardization agreements. Three-fourths of the

total width on the left side of the tape has a code color

or colors that indicate one function only per color or

colors. The function of the line is printed in English

across the colored portion of the tape. Even a

non-English-speaking person can troubleshoot or

maintain the aircraft if he/she knows the code but

cannot read English. The right-hand one-fourth of the

functional identification tape contains a geometric

design rather than the color(s) or word(s).

Figure 6-18 is a listing, in tabular form, of functions

and their associated identification media as used on

IDENTIFICATION

Fabricated tube assemblies should be identified

before installation or storage. All information from

the identification tag of the removed tube assembly

should be transferred to the tag on replacement tube

assembly. Identify the tube assemblies by ink

stamping or stenciling the part number, manu-

facturer’s code, and other required data on tube

assemblies. Apply a protective coat of clear varnish

over the markings. To aid in the rapid identification

of the various tubing systems and operating pressure,

each fluid line in the aircraft is identified by bands of

paint or strips of tape around the line near each fitting.

These identifying media are applied at least once in

each compartment. Various other information is also

applied to the lines.

Identification tapes are applied to all lines less

than 4 inches in diameter except cold lines, hot lines,

lines in oily environment, and lines in engine

compartments where there is a possibility of the tape

being drawn into the engine intake. In these cases,

Figure 6-18.—Functional identification type data.

6-16