The simple hand bender shown in figure 6-10

uses two handles as levers to provide the mechanical

advantage necessary to bend the tubing, while the

mechanical operated tube bender employs a hand

crank and gears. The forming die is keyed to the drive

gear and secured by a screw (fig. 6-11).

The forming die on the mechanical tube bender is

calibrated in degrees similar to the radius block of the

hand-type bender.

A length of replacement tubing

may be bent to a specified number of degrees or it

may be bent to duplicate the bend in the damaged tube

or pattern. Duplicating the bend of a damaged tube or

pattern is accomplished by laying the pattern on top of

the tube being bent and slowly bending the new tube

to the required bend.

NOTE: Certain types of tubing are more

elastic than others. It may be necessary to

bend the tube past the required bend to allow

for springback.

Before bending aluminum alloy tubing, it should

be packed with fusible alloy Federal Specification

QQ-F-838. In an emergency, when aluminum alloy

QQ-F-838 is not available, aluminum alloy tubing

may be packed with shot or sand and both ends closed

with protective closures before bending. Where sand

or fusible alloy is used, wash or blow out all particles

after the tubing has been bent. Particles of aluminum

alloy or sand can cause serious damage to component

parts.

TUBE JOINT PREPARATION

The two major tube joints are the flared fittings

and flareless fittings. Preparation for these tube joints

differ.

Flared Fitting

There are two types of flared tubing joints—the

single-flared joint and the double-flared joint. The

single-flared tube joint is used on all sizes of steel

tubing and 5052 aluminum alloy tubing that conforms

to Federal Specification WW-T-700/6 with 1/2 inch or

larger outside diameter,

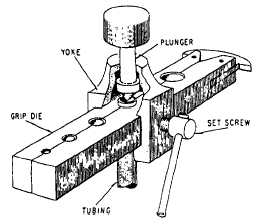

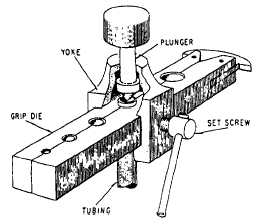

Use the tube flaring tool

(fig. 6-12) to prepare tube ends for flaring. Check

tube ends for roundness, square cut, cleanliness, and

no draw marks or scratches. Draw marks can spread

and split the tube when it is flared. Use a deburring

tool to remove burrs from the inside and outside of the

tubing. Remove filings, chips, and grit from inside

the tube. Clean the tube. Slip the fitting nut and

sleeve onto the tube. Place the tube into the proper

size hole in the grip die. Make sure the end of the

tube extends 1/64 inch above the surface of the grip

die. Center the plunger over the end of the tube and

Figure 6-12.—Tube flaring toot (single-flare).

tighten the yoke setscrew to secure the tube in the grip

die and hold the yoke in place. Strike the top of the

plunger several light blows with a hammer or mallet,

turning the plunger a half turn after each blow.

Loosen the setscrew and remove the tube from the

grip die.

Check to make sure that no cracks are

evident and that the flared end of the tube is no larger

than the largest diameter of the sleeve being used.

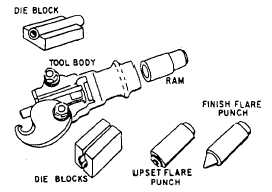

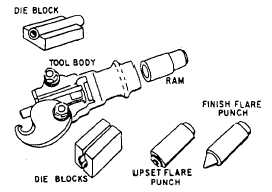

The double-flare tube joint is used on all 5052

aluminum alloy tubes with less than 1/2-inch outside

diameter, except when used with NAS 590 series tube

fittings and NAS 591 connectors or NAS 593 con-

nectors. Aluminum alloy tubing used in low-pressure

oxygen systems or corrosion-resistant steel used in

brake systems must be double flared. Double flare

reduces the chance of cutting the flare by

overtightening. When fabricating oxygen lines, make

sure that all tube material and tools are kept free of oil

and grease. Use the tube flaring tool (fig. 6-13) to

prepare tube ends.

Check tube end for roundness,

square cut, cleanliness, and make sure there are no

draw marks or scratches. Draw marks can split the

tubing when it is flared.

Figure 6-13.—Tube flaring tool (double-flare).

6-11