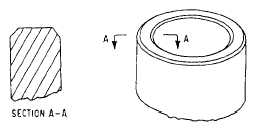

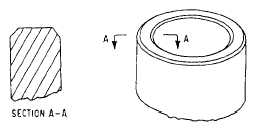

Figure 6-7.—Properly deburred tubing.

If neither tube cutter (standard or Permaswage) is

available, a fine-tooth hacksaw should be used to cut

tubing. A convenient method for cutting tubing with a

hacksaw is to place the tube in a flaring block and the

clamp block in a vise. After cutting the tube with a

hacksaw, remove all saw marks by filing the tube.

Tube Deburring

After you cut the tubing, remove all burrs and

sharp edges from inside and outside of tube (fig. 6-7)

with deburring tools. Clean out tubing. Make sure

that no foreign particles remain. A Permaswage

deburring tool may be used to remove burrs from

inside of tubing.

Select deburring tool and stem

subassembly (fig. 6-8) required for the size of tubing

to be deburred. Lubricate the sliding collar on the end

of elastic plug with light oil if necessary to get free

movement.

Engage threads and insert stem

subassembly into cutter end of deburring tool by

depressing the plunger, and screw stem subassembly

into plunger until it bottoms and fingertightens.

Check assembly deburring tool. Depress plunger and

the plug. Outside diameter should be reduced to the

same diameter as metal support collar on either end of

elastic plug. Release plunger. Two distinct circum-

ferential bumps will appear on elastic plug beyond

outside diameter of metal support collars. Check the

tube end for squareness. Check the elastic plug for

wear and cleanliness. Replace worn or damaged

elastic plug. Clean and lightly lubricate elastic plug

with lubricant compatible to hydraulic fluid to be used

Figure 6-8.—Permaswage deburring foot (typical).

in tubing. Grasp deburring tool in one hand with two

fingers on collar and thumb on plunger. Depress

plunger with thumb and insert elastic plug into tube

opening until cutter is about 1/8 inch from tube end.

If the plug fit is tight due to a large burr on ID of the

tube, slowly rotate the plunger end of tool while

gently pushing tool into the tube end. Release

plunger to allow elastic plug to expand and seal tube

opening to prevent chips from entering. Hold tube

end and rotate knurled body of deburring tool in a

clockwise direction while applying pressure to cutter.

Continue rotating tool until resistance decreases,

indicating all burrs have been removed from tube ID.

You should avoid excessive deburring, which can

cause too deep a chamfer on tube ID. The chamfer

should not exceed one-half wall thickness of tubing.

Relax pressure and rotate deburring tool several times

to produce a smooth surface. Without depressing

plunger, ease deburring tool from tube until the first

bulge of elastic plug is exposed. Wipe off the tube

end and plug.

Check the tube end to see if it is

completely deburred. If tube end appears saticfactory,

without depressing plunger, remove deburring tool

from tube. If tube end is not completely deburred,

without depressing plunger, push deburring tool back

into the tube and repeat all the steps.

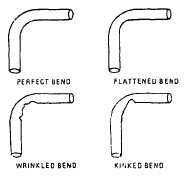

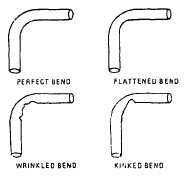

TUBE BENDING

The objective in tube bending is to obtain a

smooth bend without flattening the tube. Acceptable

and unacceptable bends are shown in figure 6-9.

Tube bending is usually done by using a mechanical

or hand-operated tube bender. In an emergency, soft,

nonheat-treated aluminum tubing smaller than

1/4 inch in diameter may be bent by hand to form the

desired radius.

Figure 6-9.—Tubing bends.

6-9