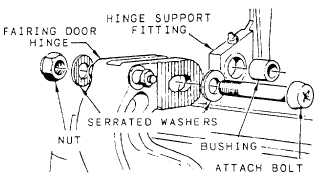

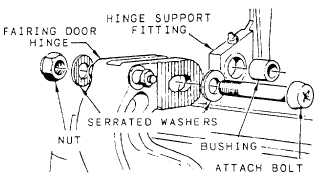

Figure 12-7.–Adjustable door hinge installation.

Landing gear doors have specific allowable

clearances that must be maintained between doors and

the aircraft structure or other landing gear doors. These

required clearances can be maintained by adjusting the

door hinges and connecting links and trimming excess

material from the door if necessary.

On some installations, door hinges are adjusted by

placing the serrated hinge and serrated washers in the

proper position and torquing the mounting bolts, which

allows linear adjustments. Figure 12-7 shows this type

of mounting. The amount of linear adjustment is

controlled by the length of the elongated bolt hole in the

door hinge.

SHOCK STRUTS

Shock struts are self-contained hydraulic units.

They carry the burden of supporting the aircraft on the

ground and protecting the aircraft structure by absorbing

and dissipating the tremendous shock of landing. Shock

struts must be inspected and serviced regularly for them

to function efficiently. This is one of your important

responsibilities.

Each landing gear is equipped with a shock strut. In

addition to the landing gear shock struts, carrier aircraft

are equipped with a shock strut on the arresting gear.

The shock strut’s primary purpose is to reduce arresting

hook bounce during carrier landings.

Because of the many different designs of shock

struts, only information of a general nature will be

included in this chapter. For specific information on a

particular installation, you should refer to the applicable

aircraft MIM or accessories manual.

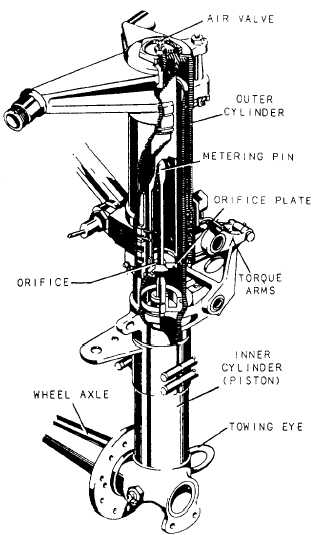

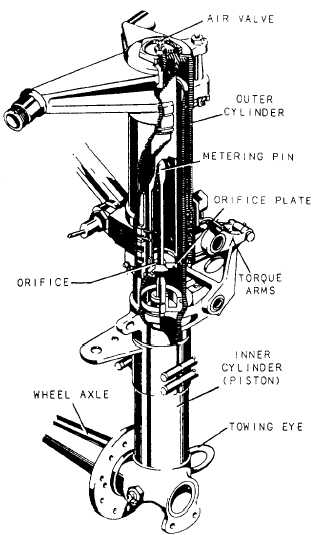

A typical pneumatic/hydraulic shock strut

(metering pin type) is shown in figure 12-8. It uses

compressed air or nitrogen combined with hydraulic

fluid to absorb and dissipate shock, and it is often

Figure 12-8.–Landing gear shock strut (metering pin type).

referred to as the “air-oil” type strut. This particular strut

is designed for use on the main landing gear.

As shown in the illustration, the shock strut is

essentially two telescoping cylinders or tubes, with

externally closed ends. When assembled, the two

cylinders, known as cylinder and piston, form an upper

and lower chamber for movement of the fluid. The lower

chamber is always filled with fluid, while the upper

chamber contains compressed air or nitrogen. An orifice

(small opening) is placed between the two chambers.

The fluid passes through this orifice into the upper

chamber during compression, and returns during

extension of the strut.

Most shock struts employ a metering pin similar to

that shown in figure 12-8 to control the rate of fluid flow

from the lower chamber into the upper chamber. During

the compression stroke, the rate of fluid flow is not

constant, but is controlled automatically by the variable

shape of the metering pin as it passes through the orifice.

12-8