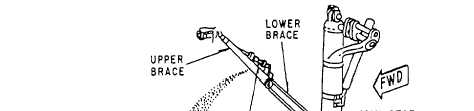

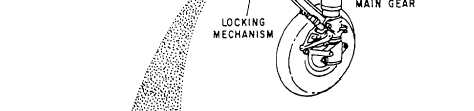

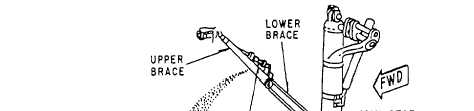

Figure 12-12.–Landing gear drag brace adjustment.

permit the brace to jackknife during retraction of the

gear. The upper brace pivots on a trunnion attached to

the wheel well overhead. The lower brace is connected

to the lower portion of the shock strut outer cylinder.

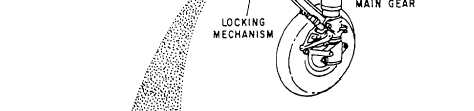

On the drag brace shown in figure 12-12, a locking

mechanism is used where the lower and upper drag

braces meet. Usually in this type of installation, the

locking mechanism is adjusted so that it is allowed to be

positioned slightly overcentered. You must be able to

inspect and adjust landing gear braces and lccking

mechanisms as specified in the applicable MIM.

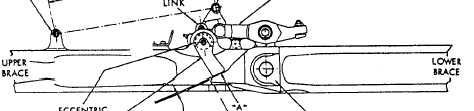

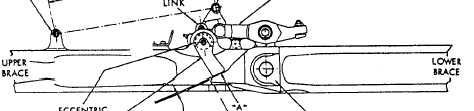

To adjust the drag brace shown in figure 12-12, you

would first remove the cotter pin and nut (not shown)

from the lock arm shaft. With the drag brace in the full

extended position, rotate the eccentric bushings that are

located on each end of the lock arm shaft.

Both bushings must be rotated together to ensure

that the high point of the eccentricity is the same on both

bushings. Failure to do this may result in damage to the

equipment or sluggish operation. The bushings maybe

rotated in either direction until the end of the leek arm

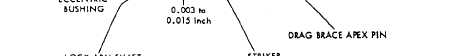

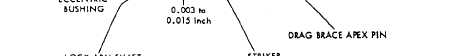

shaft, shown as point “A” in figure 12-12, is a distance

of 0.003 inch to 0.015 inch from the striker. This

clearance is checked with a feeler gauge.

Other portions of the drag brace are nonadjustable,

except for the length of its down leek cylinder. Figure

12-12 indicates the cylinder should be adjusted to a

length of 12 3/8 inches.

In the design of drag braces, the tendency has been

directed toward lessening the adjustment requirements.

In some installations, drag braces are manufactured to

exact dimensions and do not require adjustments.

NOSEWHEEL STEERING SYSTEMS

Learning Objective: Recognize the types of

nosewheel steering systems, their components,

and the applicable main tenance requirements.

12-11