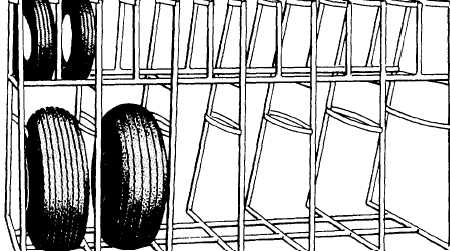

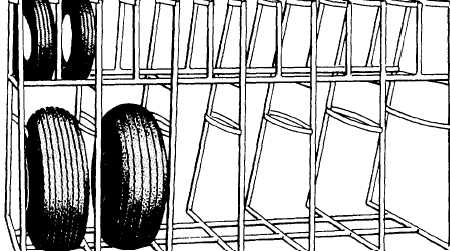

Figure 11-15.—Tire storage rack (varied size tires).

second method uses four or more vent holes that

extend completely through each tire sidewall. They

relieve both pocketed air and air that accumulates in

the cord body by normal diffusion through the inner

tube and tire. Tube tire vent holes are marked with an

aluminum- or white-colored dot.

Tubeless tires have vent holes that penetrate from

the outside of the tire sidewall to the outer plies of the

cord body. They relieve air that accumulates in the

cord body by normal diffusion through the tubeless

tire liner and the tire carcass. Vent holes in tubeless

tires are marked with a bright green dot.

NOTE: Rebuilt tires may not have the vent

holes clearly marked.

TIRE STORAGE

The life of a tire, whether mounted or unmounted,

is directly affected by storage conditions. Tires

should always be stored indoors in a dark, cool, dry

room. It is necessary to protect them from light,

especially sunlight.

Light causes ultraviolet (UV)

damage by breaking down the rubber compounds.

The elements, such as wind, rain, and temperature

changes, also break down the rubber compounds.

Damage from the elements is visible in the form of

surface cracking or weather checking. UV damage

may not be visible. Tires can be protected from light

by painting the storeroom windows. Tires must not

be allowed to come in contact with oils, greases,

solvents, or other petroleum products that cause

rubber to soften or deteriorate. The storeroom should

not contain fluorescent lights or sparking electrical

equipment that could produce ozone.

Tires should be stored vertically in racks and

according to size. See figure 11-15. The edges of the

racks must be smooth so the tire tread does not rest on

a sharp edge.

Tires must never be stacked in

horizontal piles. The issue of tires from the storeroom

should be based on age from the date of manufacture

so the older tires will be used first. This procedure

helps to prevent the chance of deterioration of the

older tires in stock.

TIRE INSPECTION

There are two types of inspections conducted on

tires. One is conducted with the tire mounted on the

wheel. The other inspection is conducted with the tire

dismounted.

Mounted Inspection

During each daily or special inspection, tires must

be inspected for correct pressure, tire slippage on the

wheel (tube tires), cuts, wear, and general condition.

Tires must also be inspected before each flight for

obvious damage that may have been caused during or

after the previous flight.

Maintaining the correct inflation pressure in an

aircraft tire is essential to safety and to obtain its

maximum service life. Military aircraft inner tubes

and tubeless tire liners are made of natural rubber to

satisfy extreme low-temperature performance

requirements. Natural rubber is a relatively poor air

retainer. This accounts for the daily inflation pressure

loss and the need for frequent pressure checks. If this

check discloses more than a normal loss of pressure,

you should check the valve core for leakage by

11-16