217.181

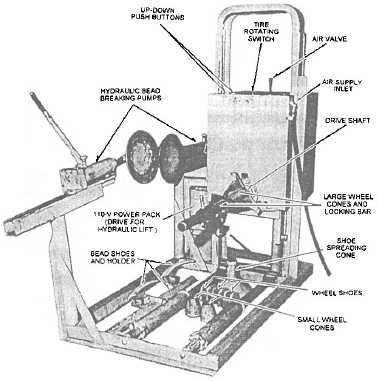

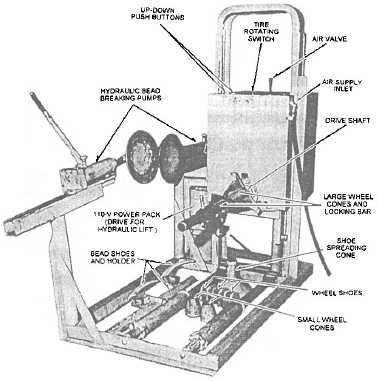

Figure 11-18.—Aircraft wheel holder and tire bead-breaking machine.

takeoff speeds. Carrier operations place extra demands

on the tire maintenance. In many cases tire failures are

attributed to material failures and/or manufacturing

defects when actually improper maintenance was the

underlying cause. Poor inspection, improper buildup,

operation of tires in an underinflated or overinflated

condition are common causes for tire failure. Strict

adherence to proper inspection procedures and

maintenance instructions is mandatory. This will ensure

that sound tires with minor discrepancies will not be

removed prematurely, unsafe tires will be replaced

before flight, and worn tires will be removed at the

proper time to permit rebuilding.

During the mounting, dismounting, and inflating of

tires, safety is paramount. Compressed air and nitrogen

present a safety hazard if the operator is not aware of

the proper operation of the inflation equipment and the

characteristics of the inflation medium. It is also very

important to know the wheel type and be familiar with

the manufacturer’s recommended procedure before you

attempt to dismount a tire. For specific precautions

concerning a particular installation, you should always

consult the applicable MIM.

Dismounting

In the tire shop, you should recheck tires for complete

deflation before disassembling the wheel and breaking

the bead of the tire. Breaking the bead means separating

the bead of the tire from the wheel flange. When a tire

has been completely deflated and set aside to await the

bead-breaking operation, the valve core should be

removed and a deflated tire tag installed on the valve

stem. The tire tags should be so constructed as not to be

installable unless the valve core has been removed.

Refer to figure 11-5.

BREAKING THE BEAD.—The use of proper

equipment for breaking the bead of the tire away from

the wheel flange will save materials and man-hours.

Aircraft tires, inner tubes, and wheels can be damaged

beyond repair by improper mounting and dismounting

equipment and procedures. Always refer to the

applicable manufacturer’s operating manual prior to

using this equipment. The equipment shown in figure

11-18 is recommended in NAVAIR 04-10-506. Other

commercially available or locally fabricated equipment

that uses either a hydraulically actuated cylinder or a

mechanically actuated device may also be used, provided

the equipment will not damage the

11-19