torque required for the wheel. Use a calibrated torque

wrench, and tighten each bolt in increments of 25

percent of the specified torque value in a crisscross

order until the total torque value required for each bolt

in the wheel has been reached.

NOTE: When lubtork is specified on the

wheel half, coat all the treads and bearing

surfaces of the bolt heads with MIL-T-5544

antiseize compound.

Lubtork must not be

used on magnesium wheels. For magnesium

wheels, you should use MIL-G-21164

lubricant. All excessive lubricant should be

removed.

Before mounting tubeless tires, check the tire

side wall for the word tubless. Tires without this

marking should be treated as tube tires. When you

mount tubeless tires, install the valve stem (valve core

removed) in the wheel assembly. Removing the valve

core prevents unseating of the wheel seal by the

pressure built up when the tire is installed. Insert one

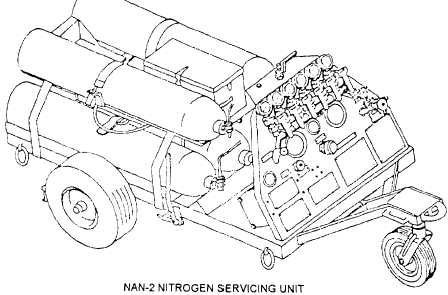

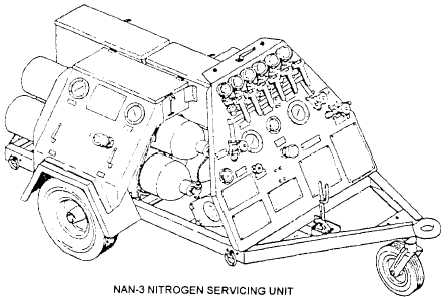

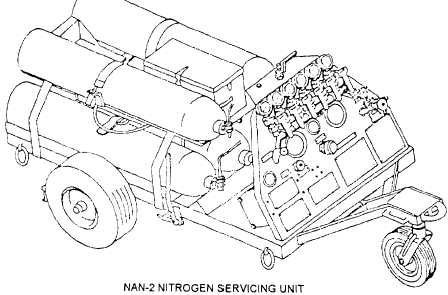

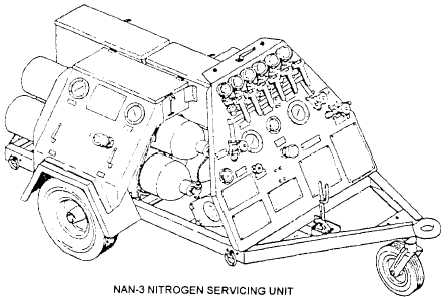

Figure 11-21.—Nitrogen servicing units.

11-22