wheel half in the tire, and position the tire so the

balance marker on the tire is located at the valve stem.

Install the wheel seal. Be sure the outer wheel half

has been lubricated with a light coat of MIL-G-4343

lubricant. Install the other wheel half and align the

bolt holes. Install the bolts, washers, and nuts in the

same manner used for the wheel assembly containing

inner tubes.

MOUNTING REMOUNTABLE FLANGE

WHEELS.—When you mount a tube tire on a

remountable flange wheel, the inner tube should be

prepared and inserted in the tire in the same manner

used on a split or divided wheel. The wheel is then

positioned on a flat surface with the fixed flange

down. Push the tire on the wheel assembly as far as it

will go, and guide the valve stem into the valve slot

with the fingers. Install the remountable flange on

the wheel. Secure the locking ring according to the

assembly instructions required by the applicable

wheel manual.

When you mount a tubeless tire on a demountable

flange wheel, install the valve stem (valve core

removed) in the wheel assembly. Removing the valve

core prevents unseating the wheel seal by the pressure

built up when the tire is installed. The wheel seal

should be lubricated with the same lubricant and in

the same manner as previously mentioned for split or

divided wheel assemblies using tubeless tires. Install

the wheel seal on the flange. Secure the locking ring

according to the assembly instructions required by the

applicable wheel manual.

Tire Inflating

According to Federal Specification BB-N-411,

water-pumped nitrogen should be used to inflate tires.

When nitrogen is not available, dry, oil-free air may

be used. Nitrogen is provided in a number of mobile

carts. The NAN-2 and NAN-3 carts are shown in

figure 11-21. Tire shops are generally equipped with

a bulkhead nitrogen outlet.

All high-pressure inflation sources should be

equipped with a regulator that limits the line pressure

to the remote inflator assembly. The regulator should

be set to provide a controlled inlet pressure to the

inflator. It should not exceed the required tire

inflation pressure by more than 50 percent or 600 psi,

whichever is less.

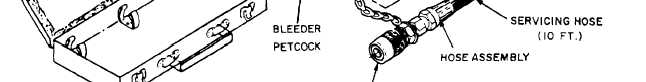

The tire inflator assembly kit is an excellent

maintenance device if it is used and cared for

according to the NAVAIR 17-1-123 manual. See

figure 11-22. This manual includes the operation

Figure 11-22.—Tire inflator assembly kit.

11-23