tires or wheels. The bead-breaking equipment shown

in figure 11-18 is available in two models. The Lee-I

model is designed for use at shore-based facilities.

The Lee-IX model is an explosionproof version of the

Lee-I, and is intended for shipboard use.

An example of the steps used for bead breaking

using the Lee-I equipment follows:

1. Ensure the tire is completely deflated.

2. Determine the type and size of the wheel to be

dismounted, and assemble the proper parts on the

drive shaft.

3. Push the outer centering rollers toward the

front of the machine, and roll the wheel (positioned

with the lockring side facing outward for

remountable flange wheels) on the outer centering

rollers. You should use the up and down push buttons

to raise or lower the drive shaft to the proper height

for the wheel being dismounted. Push the wheel onto

the drive shaft. If an open-rimmed tire assembly is

being dismounted, omit step 4 and proceed to step 5.

4. Insert the locking bar and turn it about 90

degrees counterclockwise. Mount the wheel cone on

the locking bar and insert the locking pin.

5. Push the air valve switch to the right. This will

clamp the wheel on the drive shaft.

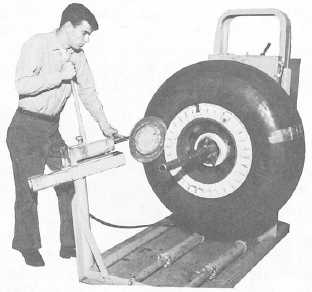

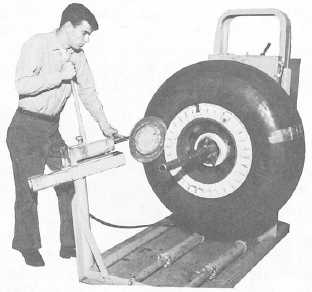

217.182

Figure 11-19.—Using bead-breaking pump.

6. Use the UP push button to raise the center of

the wheel to line up with the center of the bead-

breaking disc.

7. Rotate the tire by pushing the tire rotating

toggle to the right. Position the front bead-breaking

disc against the outside bead of the wheel flange. You

should adjust the position of the hydraulic pump

assembly by loosening the position lockpin and

sliding the pump to the proper position. After turning

the pump release valve clockwise as far as it will go,

apply hydraulic pressure against the bead by

pumping the handle, as shown in figure 11-19. Use

the guide handle to properly position the disc. Push

the bead back far enough to allow the removal of the

lockring or loose flange.

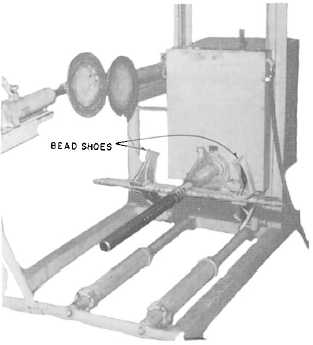

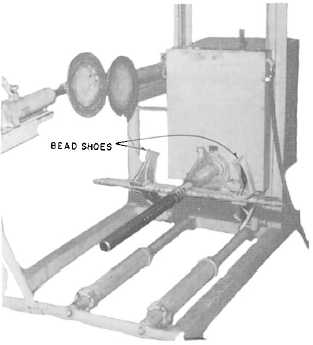

8. Remove the lockring and loose flange. You

should use the bead shoes to hold the bead back while

you are removing the lockring. See figure 11-20.

Release and retract the front bead-breaking disc by

turning the release valve counterclockwise.

9. Repeat the bead-breaking operation against the

rear surface of the tire with the rear bead-breaking

assembly.

217.183

Figure 11-20.—Shaft arranged to hold tire bead

while removing lockring.

11-20