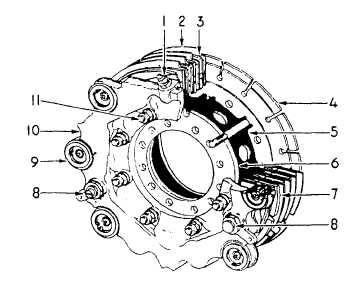

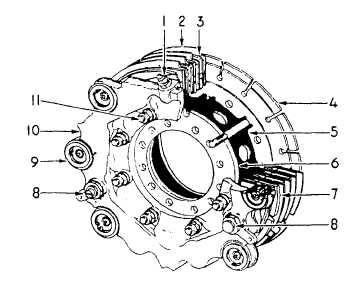

1. Bleeder valve

7. Pressure plate subassembly

2. Rotating disc

8. Brake inlet port

3. Stationary disc

9. Self-adjusting mechanism

4. Housing backplate

10. Brake housing subassembly

5. Keyed torque tube

11. Brake assembling bolt

6. Torque tube spacer

Figure 12-53.—Trimetallic brake assembly.

the next locking position, as shown in view F. Secure

the threaded retainer with the wire retaining ring.

Replace the piston packings with new packings that

have been dipped in hydraulic fluid, and ensure that the

packings and adjusting pin stems are lubricated with

hydraulic fluid.

The piston assemblies are then installed in the

cylinder housing and forced to the complete brake-off

positions–bottomed in the housing cavities. The pistons

are supported against their linings to the brake-off

position. Use the press and the grip driver, as illustrated

in view G, to force the grips, one at a time, over the

adjusting pins until they are bottomed. The pistons must

remain in the complete brake-off position when the grips

are installed. Place the spacers over the adjusting pins

and install the bushings fingertight. Hold the bushings

in fingertight positions and install and tighten the

locknuts. Safety wire the locknuts, as shown in view H.

NOTE: On some brake assemblies, the ad-

justing pin bushing (adjusting pin nut) is

torqued to a specified value.

The brake assembly must be tested following

reassembly. Connect the brake assembly to a hydraulic

supply source. Bleed the brake assembly and apply 600

psi.

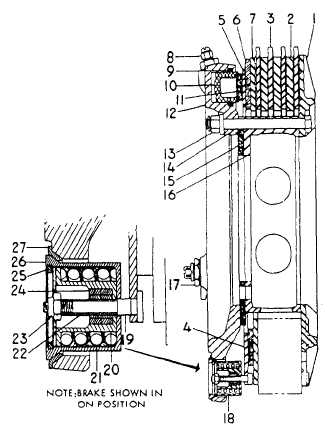

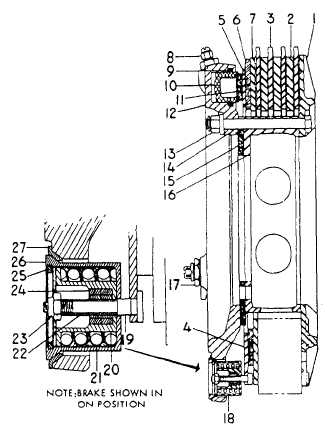

1. Housing backplate

2. Stationary discs

3. Rotating discs

4. Pressure plate subassembly

5. Pressure plate

6. Wear plate insulator

7. Wear plate

8. Bleeder valve

9. O-ring and backup ring

10. Piston

11. Piston insulator

12. Brake housing subassembly

13 Self-locking nut

14. Brake assembling bolt

15. Torque tube spacer

16. Keyed torque tube

17. Inlet bushing

18. Self-adjusting

mechanism

19. Self-adjusting pin

20. Return-spring guide

21. Return spring

22. Self-adjusting pin tube

23. Self-locking nut

24. Split collar grips

25. Retalning ring

26. Spring housing

27. Spring housing bushing

Figure 12-54.—Trimetallic brake assembly-cross section.

CAUTION

Before applying pressure, make sure that the

brake is assembled properly with all bolts

torqued and brake discs in position. Failure

to do so could result in injury to personnel.

Hold the test pressure for 2 minutes while you are

checking the brake assembly for leaks. Release and

apply the pressure 10 times to be sure that the brake

functions properly. The brake discs should be free when

hydraulic pressure is released. Allow the brake to stand

for 2 minutes with pressure released and check for static

fluid leakage.

12-60