1. Bead ledge

2. Bead seat radius

3. PilotPtlot

4. Tubewell seal

5. Brake key

6. Valve stem

7. Web

8. Spoke or face

9.

10.

11.

12.

13.

14.

15.

16.

Hub seal

17. Bearing cup

Retaining ring

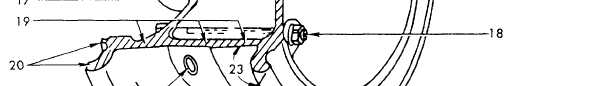

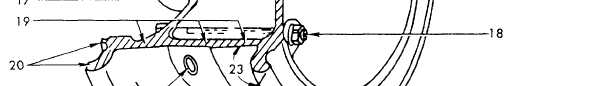

18. Tie-bolt & nut

Hub

19. Tubewell I.D. surface

Grease retainer

20. Rim flange

Bearing retaining shoulder

21. Tubewell O.D. surface

Hub cap

22. Fusible plug

Hub cavity

23. Rim

Bearing cone & rollers

Figure 11-1.—Typical divided (split) wheel assembly.

The demountable flange is attached to the wheel

to simplify tire removal and installation. The

remountable flange lockring secures the flange to the

wheel. The flange is fitted into a groove in the wheel

casting.

The bearing cups are shrink-fitted into the hub of

the wheel casting, and are the parts on which the

bearings ride.

The bearings are tapered roller

bearings. Each bearing is made of a cone and rollers.

This type of bearing absorbs side thrust as well as

radial loads and landing shocks. These bearings must

be cleaned and lubricated in accordance with the

NAVAIR 04-10-1 manual.

A three-piece grease retainer keeps the grease in

the inboard bearing and keeps out dirt and moisture.

It is composed of a felt seal and inner and outer

closure rings. A lockring secures the assembly inside

the wheel hub.

The hubcap seals the outboard side of the hub. It

is secured with a lockring.

On some aircraft, the

hubcap is secured with screws.

All wheels designed to be used on the main

landing gear are equipped with braking components.

These components are attached to the wheel casting.

They may consist of either a brake

drive keys.

The wheel shown in

drum or brake

figure 11-3 is

11-2