head by running the rotor brake disc. The hydraulic

disc motor operates only after the gear train engages

the teeth of the rotor brake disc. Pressure is cut off to

the blade rotation control valve and the motor by the

sequence valve. This action occurs when the gear

train has been operated to disengage the rotor brake

disc.

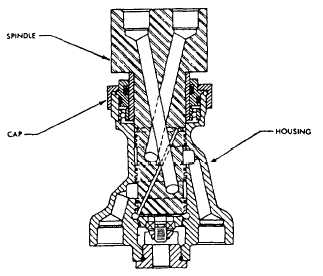

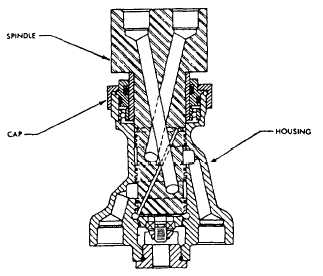

ROTOR COUPLING.—The rotor coupling is

found at the bottom of the rotary-wing shaft. It serves

to transfer hydraulic fluid to the rotary-wing head for

blade folding. Figure 10-14 shows a cross-sectional

view of the coupling.

The coupling consists of a

spindle that revolves with the rotary-wing shaft. A

stationary housing connects to hydraulic lines of

blade folding components. Hydraulic fluid is sent

through the rotor coupling, and then through the lock

valve. Pressure is then sent to the manifold, to the

damper-positioner shuttle valve, and to the

damper-positioner sequence valves.

CONTROL LOCK CYLINDER.—The control

lock cylinder is on the No. 2 blade horn assembly

rotary-wing head. During the fold cycle, the control

lock cylinder locks the flight controls. This occurs

only after the blade has been positioned. During the

spread cycle, it unlocks the controls. A microswitch

within the housing of the cylinder causes the CONT

LOCKPIN ADV advisory light in the cockpit to light.

In event of hydraulic malfunction, the control lockpin

may be operated manually. This is done by turning a

sector gear bolt on the aft end of the cylinder. The

sector bolt rotates gear teeth on the end of the

actuating piston shaft.

BLADE FOLD ACCUMULATOR.—A blade

fold accumulator is found inside of the rotary-wing

sleeve of the No. 1 blade. It has a preload of 1,500-psi

nitrogen pressure to maintain hydraulic pressure in

the rotary-wing head. The pressure is necessary to

keep the damper-positioners extended and the blade

locked in the folded position. It serves to compensate

for expansion and contraction of the hydraulic fluid

because of temperature changes. It also dampens out

pressure surges during fold and spread cycles.

AUTOMATIC BLADE FOLDING SYSTEM

MAINTENANCE

Maintenance of the blade fold system consists of

periodic inspection, lubrication, operational testing,

and troubleshooting. Allowable maintenance at the

organizational level includes alignment, adjustment,

and the removal and installation of components. Parts

Figure 10-14.—Rotor coupling.

replacement and cure date kits are available for

intermediate-level repair of defective parts. Before

removal of any component, secure the blades to

prevent damage. Whenever any part of the system is

repaired or replaced, the electrical portion of the

system should be tested, as required by the MIM.

Operationally check the entire hydraulic portion of

the system to ensure proper sequence of operation.

The hydraulic testing procedures discussed in the

following paragraphs are used as an example. Always

consult your MIM for correct procedures.

Charge the air accumulator with 1,500 psi of

nitrogen, with the blades in the spread position.

Connect a source of external hydraulic power to the

utility, primary, and auxiliary hydraulic systems. Set

pressure to 3,000 psi at approximately 3 gallons per

minutes for the utility system. Set pressure to 1,500

psi for the primary and auxiliary servo hydraulic

systems. Position the ACCESSORY DRIVE switch

to ACCESS DR. The accessory drive light will light.

At the start of the testing, make sure that PRI SERVO

PRESS, AUX SERVO PRESS, ACCESSORY

DRIVE, ROTOR BRAKE ON, and CHECK BLADE

FOLD lights will light. The ACCESSORY DRIVE,

FLIGHT POS, BLADE SPREAD, EXT PWR ON,

PRI SERVO PRESS, and AUX SERVO PRESS lights

should be lit. Visually check to see that the lockpins

are disengaged. Manually rotate the rotary head until

the leading edge of the No. 1 blade is in the aft

position. Engage the rotor brake. The rotor brake

pressure gauge should read a minimum of 320 psi.

Check that the rotor brake light comes on. Place the

collective pitch stick in the full low position and the

10-19