instructions provided in the applicable aircraft

MIM.

NOTE: While performing maintenance on any

system, ensure that the step-by-step procedures

outlined in the MIM including CAUTIONS,

WARNINGS, and SAFETY notes concerning the

specific procedures are strictly complied with.

7. Conduct a final operational check. The

affected component or system must be given an

operational check following installation or repair

to verify proper system or component operation.

The MIM will provide the procedures for

conducting the operational check. It will usually

require operation of the system in various modes

(manual and automatic for air-conditioning and

pressurization systems) or through several cycles,

as applicable. Specified steps throughout the

repair procedure and operational check must be

observed and certified by a quality assurance

representative or a collateral duty quality

assurance representative from the work center

performing the work. These steps are usually

identified in the MIM by underlining, italics, or

some other obvious method.

MULTIMETER TROUBLESHOOTING

SKILLS

As previously mentioned, much of the AME’s

time is spent troubleshooting equipment in the

squadron’s aircraft. Troubleshooting on the S-3

aircraft environmental control system involves the

use of the multimeter to check the resistance of

the temperature sensor and to check the voltage

to electrical connectors. The material presented

in the following paragraphs will increase your

knowledge of the multimeter and increase your

proficiency as a troubleshooter. If you are not sure

of the proper and safe methods for using this

equipment, you should request the assistance of

an AE.

Multimeter

A multimeter is the most common electrical

measuring device used in the Navy. The name

multimeter comes from the words MULTIple

METER. The multimeter is a direct current (de)

ammeter, an alternating current (at) ammeter, a

dc voltmeter, an ac voltmeter, and an ohmmeter

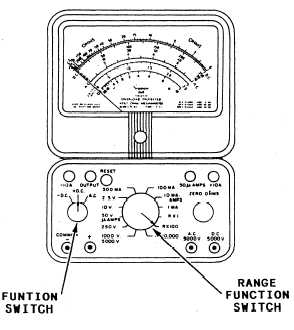

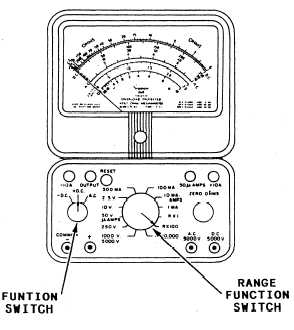

all in one package. Figure 3-23 is a sketch of a

typical multimeter. While it may look

complicated, it is very easy to use.

Figure 3-23.—A typical multimeter.

JACKS.— The lower portion of the meter

contains the function switches and jacks for the

meter leads. The COMMON or ( – ) jack is used

in most functions of the meter. One meter lead

is plugged into the common jack. The ( + ) jack

is used for the second meter lead for any of the

functions printed beside the range function switch

(the large switch in the center). The other jacks

have specific functions printed above or below

them and are self-explanatory. The output jack

is used with the dB scale and will not be explained.

To use one of the special function jacks, except

the + 10 amps, one lead is plugged into the

common jack, and the range function switch is

positioned to point to the special function desired.

For example, to measure a very small current

(20 microampere), one meter lead is plugged

into the common jack, the other meter lead is

plugged into the 50 amps jack, and the function

switch is placed in the 50V/u amps position. To

measure currents above 500 milliamperes, the

+ 10A and – 10A jacks are used for the meter

leads, and the function switch is placed in the

10MA/AMPS position.

FUNCTION SWITCHES.— The function

switch is used to select the function desired. The

– dc, + dc, ac switch selects director alternating

current and changes the polarity of the direct

current functions. To measure resistance, this

switch should be in the + dc position.

3-37