inch in diameter, attached directly to the tank

drain outlet, or trailer fill-drain outlet, is

recommended by current directives. All flare

fittings must be perfect—without dents, scratches,

or toolmarks. Do not use any antiseize compound

on threads or any cleaning compounds on sampler

parts. Contamination will result. A sampler

received without residual pressure probably leaks.

Such samplers should be rejected and returned.

Just before sampling, remove the cap from the

sampler valve; open the valve to release shipping

gas pressure, then reclose. Next, remove the valve

by disconnecting the adapter from the nipple, and

place the cylinder upright in a holder.

Attach the separator and line assembly to the

tank drain or fill-drain outlet. Using a trailer

pressure of 10 to 20 psi, let the LOX flow into

an open container, such as the receiving vessel

shown in figure 5-10, for at least 30 seconds to

purge the line. Adjust the pressure to obtain a

quiet, uniform, full flow from the separator outlet

tube.

Wipe the frost from the separator outlet tube,

and immediately insert the outlet into the sampler

tube and fill it. The filling will take approximately

1 minute. When liquid splashes in droplets over

the top, the tube assembly is full. The sampling

tube holds about 180 milliliters (6. 12 oz) of LOX,

which produces a maximum pressure of 300 psi

when vaporized in the closed sampler.

NOTE: During the filling operation, the

operator should wear a face shield, hat, gloves,

and other protective equipment as excessive

pressure will violently throw LOX from the tube

assembly.

As soon as the sampler tube is filled, remove

the separator from the sampler assembly and

install the adapter to the cylinder. Close it tightly

with end wrenches, making sure that the valve is

fully closed. Turn sampler upside down for a few

minutes to allow liquid to flow from the sampler

tube into the cylinder. Immerse the valve of the

cylinder in water to check for leaks.

PURGING

Purging and other maintenance of LOX

trailers is performed by the AS rating.

Purging is the cleansing of impurities from

oxygen systems and containers. There are two

ways to purge oxygen containers, LOX wash and

gas purging.

5-14

The LOX wash method is used on large

containers, such as storage tanks and LOX

trailers, to lower the contamination to acceptable

levels by replacing the contaminated LOX with

LOX known to be uncontaminated.

To do this, drain the container using the

buildup coil. Do NOT open the vent during this

operation. Partially fill the container with un-

contaminated LOX and allow the container to

stabilize. Build up pressure to 30 to 40 psi and

then vent the pressure to 0 psi. Repeat this opera-

tion for a total of three cycles. Take a sample and

forward it to a designated site for analysis. If the

sample is acceptable, the container may be put

into service. If the sample is not acceptable, the

container must be gas purged using hot water

pumped nitrogen.

If allowed to run dry or if odor is detected in

the system, aircraft LOX converters must be gas

purged before being put into service. Gas purg-

ing of aircraft LOX systems must be done if any

maintenance is performed on the system that

opens it to the atmosphere.

To gas purge a LOX converter, first drain the

converter of LOX. If possible, allow the converter

to warm to ambient temperature. This saves vast

amounts of nitrogen. Attach a purging device to

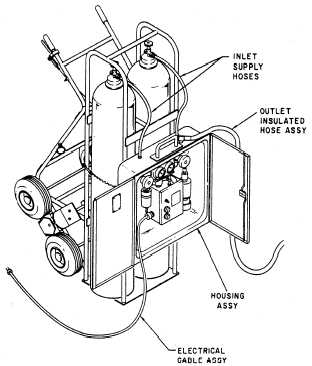

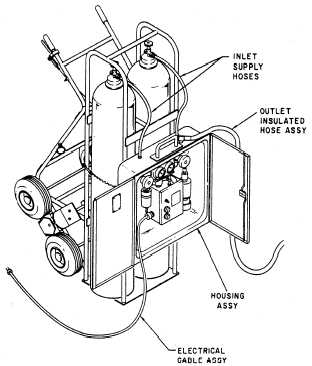

Figure 5-11.—Purging unit ready for use.