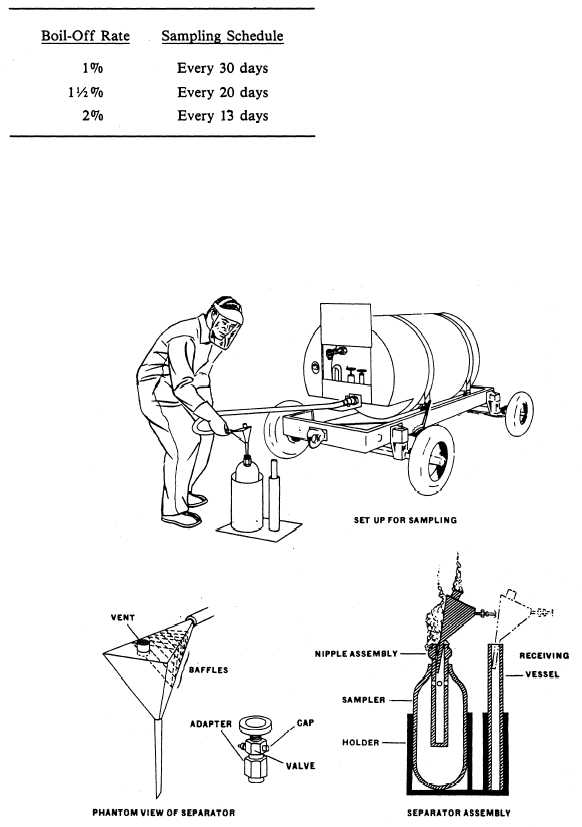

Table 5-2.—Liquid Oxygen Storage Tank Sampling Schedule

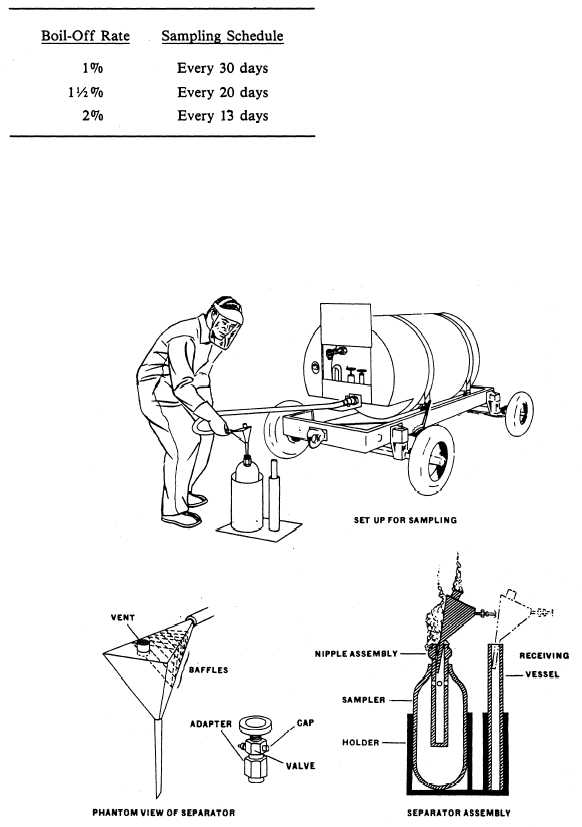

SAMPLE TAKING.— In order to exercise

rigid control over the quality of LOX

manufactured by the Navy or civilian contractors

and to test for suspected contamination, a

sample must be taken from the LOX container.

Figure 5-10 illustrates the equipment and setup

using the G-276 LOX sampler. Samplers are

prepared at depot maintenance activities and

shipped to the using activities, as required. Depot

preparation includes the separation of valve,

adapter, and cylinder; baking and evacuating the

cylinder for 1 hour, and flushing once with

gaseous oxygen; and finally, while still in the oven

and still evacuated, the cylinder is filled to 20 psi

with gaseous oxygen. The valve is then closed and

the cap installed, and then it is shipped to the

using activity.

There are several precautions that should be

observed while you are sampling. Observing these

precautions will help to ensure a representative

sample. Do not sample from a trailer hose. Use

only a short connection between the tank and

sampler. A few feet of copper tubing, three-eights

Figure 5-10.—Sampling.

5-13