228.53

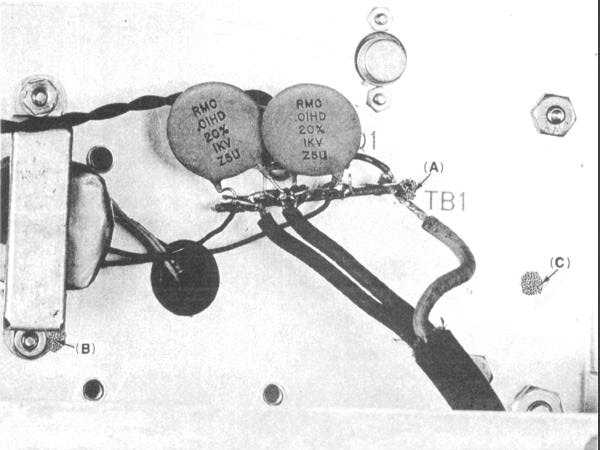

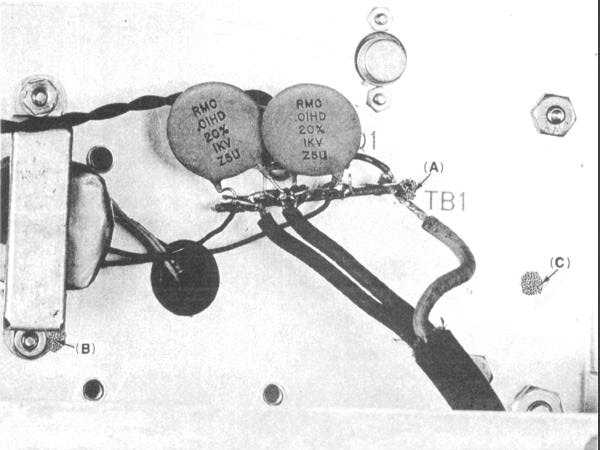

Figure 4-17.—Electrochemical corrosion.

whenever batteries are used. The battery compartment

shown in figure 4-18 needs immediate attention.

WARNING

Before performing any cleaning, inspec-

tion, or maintenance on electrical systems,

maintenance personnel should make sure that

all electrical power is secured from the air-

craft. If the electrical power is NOT secured

from the aircraft, it could result in serious

injury to maintenance personnel.

Multiple Electrical Connectors (Cannon Plugs).

Connectors mounted in avionic and electrical systems

are prone to the same corrosive environment as

airframe structural components (fig. 4-19). Normally,

connectors and mounting plates contain a gasket that

acts as a watertight seal. When maintenance personnel

dismantle (take apart) a connector for cleaning or

repair, they should inspect the gasket. They should

give special attention to connectors that use

replaceable pins. These connectors use a self-sealing

gasket water seal or dog bones (plastic inserts) that

automatically seal the connectors against water

intrusion. The repeated removal and replacement of the

pins or forgetting the dog bones may cause the watertight

seal to lose its effectiveness. In extreme cases where the

connector cannot be replaced, potting compounds must

be used to prevent water intrusion. You can find the stock

numbers for dog bones in the applicable IPB.

Coaxial Connectors. Look at figure 4-20. It shows

corrosion on a coaxial connector. Coaxial connectors

require special steps to avoid water intrusion. Usually,

moisture, contaminants, and corrosion in fuel quantity,

oil quantity, and similar capacitive-type indicating

system connectors cause erroneous (wrong) quantity

indications in the cockpit indicating systems. Antenna

coaxial connectors have similar problems with moisture.

Wire Harnesses and Cables. When corrosion is

discovered at the pin-to-wire connection on electrical

connectors, plugs, and receptacles, the wire harness

4-28