personnel inspect such areas, they should also inspect

all sections in the cooling air path, giving special

attention to obstructions and crevices where salt

deposits may build up during marine operations.

Corrosion must be checked in its early stages and paint

touch-up and hard-film, preservative coatings must be

maintained intact.

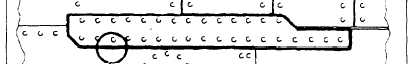

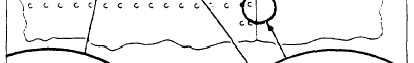

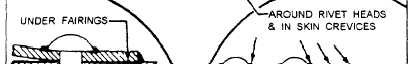

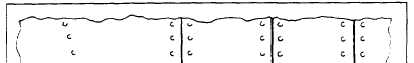

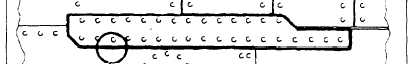

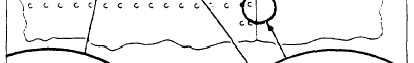

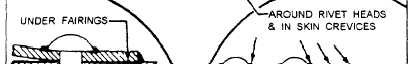

Jet exhaust deposits are very corrosive. These

deposits are particularly troublesome where gaps.

seams, hinges, and fairings are located down the

exhaust path, and where the deposits may be trapped

and not reached by normal cleaning methods. When

inspecting these surfaces, maintenance personnel

should give special attention to the areas indicated in

figure 4-23. Maintenance personnel should also

include in their inspection procedures the removal of

fairings and access panels located in the exhaust path.

JATO, Rocket, and Gun Blast Areas

Surfaces located in the path of JATO, rocket, and

gun blasts are particularly subject to corrosive attack

and decay (fig. 4-24). In addition to the corrosive

effect of the gases and exhaust deposits, protective

finishes are often blistered by heat and blasted away

by high-velocity gases. Also, spent shell casings or

solid particles from gun and rocket exhausts abrade

finishes. Maintenance personnel should watch these

areas for corrosion and clean the finishes carefully

after firing operations.

Bilge Areas

Bilge areas are common trouble spots on all

aircraft. One example of a bilge area is the engine bay

area. Bilge areas are natural collection points for

waste. hydraulic fluids, water, dirt, loose fasteners,

drill shavings, and other debris. Oil puddles often

mask small quantities of water, which settle to the

bottom and set up hidden corrosion cells. Keeping

bilge areas free of extraneous material, including oil,

is the best insurance against corrosion.

Wheel Wells and

Landing Gear

The wheel well area probably receives more

punishment than any other area on the aircraft. It is

exposed to mud, water, salt, gravel, and other flying

debris from runways during flight operations. It is

open to salt water and salt spray when the aircraft is

parked aboard ship. Because of the many complicated

shapes, assemblies, and fittings in the area, complete

coverage with a protectile paint film is difficult to

attain. Because of the heat generated from braking,

Figure 4-23.—Exhaust trail corrosion points.

4-32