205.200

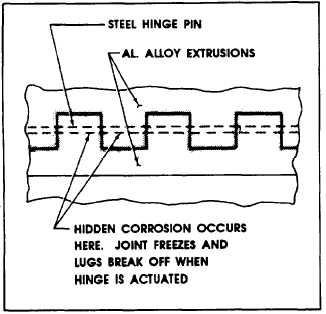

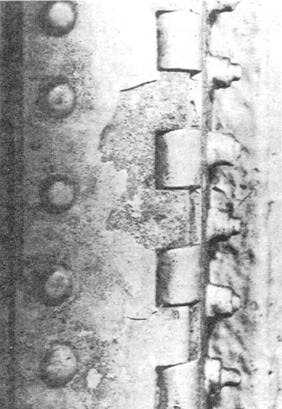

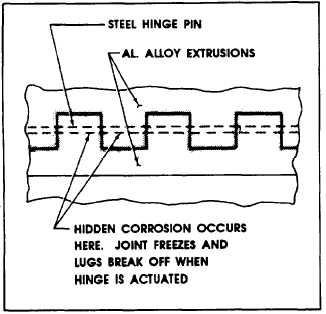

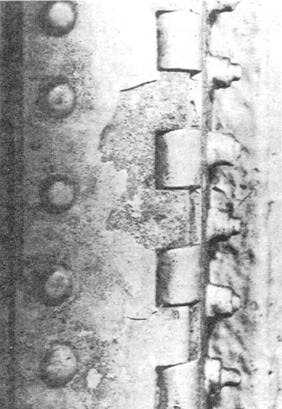

Figure 4-26.—Hinge corrosion points.

structures in avionic equipment, and the skin of the

aircraft. Because of its wide use, you must be able to

recognize and take the proper corrective action

whenever corrosion is detected or suspected.

Aluminum and its alloys are subject to a wide

range of corrosive attack, varying from general

etching of the surfaces to penetrating attacks along the

internal grain boundaries of the metal. The corrosion

products (fig. 4-27) appear as white-to-gray powdery

deposits that have greater volume than the original

metal. In its early stages, aluminum corrosion is

evident as a general etching, pitting, or roughness of

the surface. The surface attack progresses quite slowly

at first; however, the attack will accelerate if the

corroding material is not given immediate attention.

Paint coatings mask evidence of corrosion, but

because the corrosion products have a greater volume,

corrosion will show up as blisters, flakes, chips, lumps,

or other irregularities in the paint coating. Often, white

or gray streaks of corrosion products become readily

apparent at breaks in the paint film. Maintenance

personnel should investigate such signs further to

determine the extent that corrosion has progressed.

There are three types of aluminum surfaces insofar

as corrosion removal is concerned. They are clad,

anodized, and exfoliated aluminum surfaces.

Clad Aluminum Surfaces. Pure aluminum has

considerable corrosion resistance compared to

aluminum alloys. but it has little or no structural

strength. An extremely thin sheet of pure aluminum

laminated onto each side of an aluminum alloy sheet

improves the corrosion resistance with little

impairment of strength. The trade name of this

aluminum laminate, as originated by the Aluminum

Company of America, is Alcad. From this trade name

the adjective clad and the verb cladding have been

derived. An example of clad aluminum is the surface

of unpainted aircraft. Not all aircraft sheet aluminum

is clad, especially those alloy sheets from which small

brackets, gussets, and fittings are made. The pure

aluminum is very soft, and fabrication processes

would severely damage or destroy the clad surfaces.

To remove corrosion from clad surfaces, the

corroded areas should be hand polished with

MIL-P-6888 metal polish. It effectively removes

stains and produces a high-gloss, lasting polish on

unpainted clad surfaces. During the polishing

operation, you should take care to avoid mechanical

4-36